Railway Signaling Systems: Fail-Safe Relay Technology and Advanced Safety Protocols for Critical Train Control

Fundamentals of Fail-Safe Railway Signaling

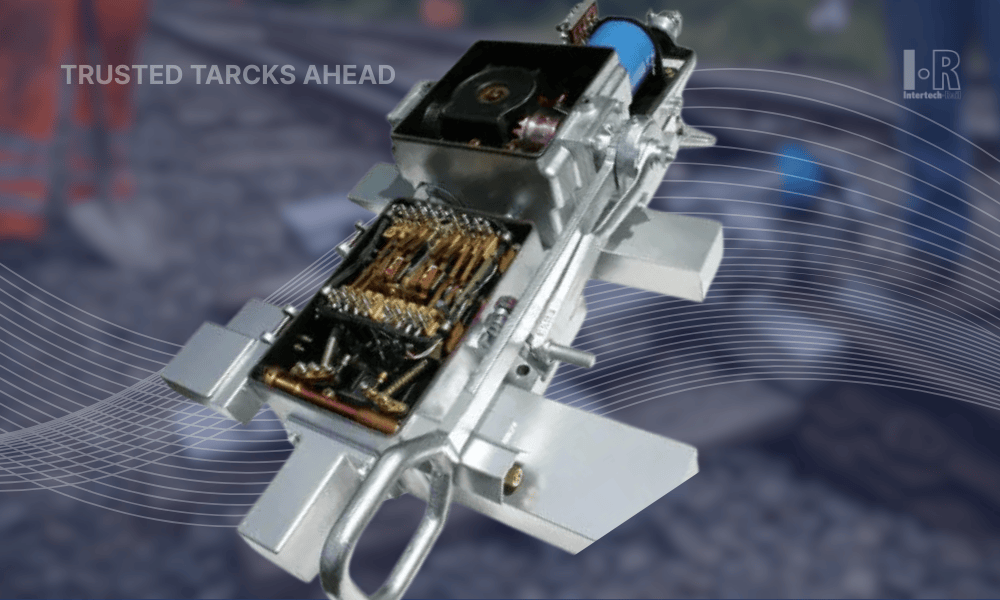

If you’ve ever stood beside a live track, you know how alive a railway feels, wires humming, switches clicking, air vibrating as a train passes. Behind all that motion, there’s an invisible discipline: safety built into every signal. And at the core of it sits a small, unassuming device, the fail-safe relay.

Fail-safe relays are the foundation of railway safety. They follow one simple law: when something fails, the system must fail safely. Power loss, broken wire, heat spike, no matter what happens, the safest state wins.

That mindset defines railway control. You don’t gamble with a moving train; you engineer certainty.

The Logic of Safety

Every circuit in a signaling system is designed to choose caution over convenience. If a signal goes dark, it turns red by default. If a relay coil burns out, the train doesn’t move. Reliability and redundancy define critical train control.

Two circuits do the job of one. Each path mirrors another. The idea isn’t to make equipment immortal, it’s to make failure predictable. In a world where seconds decide lives, that predictability is everything.

For a deeper look at global fail-safe principles and signaling standards that define modern train control, see Intertech Rail’s article Railway Safety Systems.

Relays: Old Hardware, New Relevance

There’s something beautiful about how these devices work. No screens, no processors, just metal, magnets, and movement. They click with confidence, mechanical proof that electricity still obeys physics. Even with digital interlockings and AI-based monitoring coming in, the old relay remains. It’s not nostalgia; it’s trust earned through decades. Relays don’t crash, freeze, or reboot. They operate in heat, vibration, and noise without losing logic. And that’s exactly why they still guard the heart of modern signaling systems.

Intertech Rail and the Modern Fail-Safe

Intertech Rail's fail-safe relay technology

is designed to evolve quietly, with more precise coils, better contacts, improved insulation, and tighter tolerances. Each relay goes through brutal testing for vibration, temperature, and voltage before it ever sees a cabinet.

At the same time, the company’s digital monitoring tools ( for instance, the Rail-ID® AEI System) close the gap between mechanical and electronic reliability. Modern relays now pair with sensors that track heat, resistance, and current drift in real time. When numbers shift, maintenance teams get a heads-up before faults show in the field. That’s fail-safe thinking in the data age.

Why Redundancy Works

Redundancy may look like overkill, but in railways, it’s insurance. Every relay has a partner; every signal has a shadow circuit waiting to take over. The point isn’t perfection, it’s survival through failure.

Lightning strikes, humidity rises, wires corrode. Still, the system stays calm. When one voice goes silent, another repeats the same instruction. That’s what keeps trains moving safely day after day.

A System That Teaches Itself

Signaling used to end when the relay clicked off. Now it begins there. Data from sensors and diagnostic logs feed back into maintenance platforms, helping engineers see patterns, where heat builds up, where wear starts, and where replacement cycles should change. Over time, that feedback turns routine maintenance into strategy. Fail-safe systems stop being just protection; they become lessons in reliability.

For more on how real-time diagnostics and predictive analytics improve reliability in railway operations, see Intertech Rail’s article Railway Predictive Maintenance.

The Human Factor

Ask anyone who’s spent nights inside a signal house during a storm: you never forget that sound, relays snapping like heartbeats, calm and precise. There’s comfort in that rhythm. It means the system’s still alive, still choosing safety with every pulse.

The balance railways keep chasing is human judgment guided by machine discipline.

Looking Forward

Train control

won’t abandon the relay; it will surround it with intelligence. Software will predict, sensors will listen, and relays will still decide the outcome.

Because a fail-safe isn’t a feature, it’s a promise that no signal ever lies, even when the power does.

Image Source: jmvlpsltd / IntertechRail