Railway Safety Systems: Fail-Safe Relay Technology and Signaling Standards for Critical Infrastructure Protection

Fail-Safe Design Philosophy in Railway Safety

Every rule in railway engineering begins with one word: safety. Before speed, before efficiency, before comfort, safety comes first, and it never negotiates.

Safety is built on fail-safe principles and global standards. That philosophy has shaped every signal, relay, and circuit since the first train left the station. It’s what keeps the world’s most complex transport network predictable in the face of chaos, weather, power loss, human error, and even time itself.

The Logic Behind Fail-Safe

The idea is simple: when something fails, it must fail safely. A dark signal defaults to red. A relay without power relaxes into its safest position. The system always chooses protection over progress.

In practice, that means designing circuits and relays that assume the worst and still behave correctly. Engineers build redundancy so that one broken contact or wire doesn’t decide the fate of an entire line. This principle lives inside every railway safety system, from small branch lines to high-speed networks that cross continents.

For more on how fail-safe relay technology supports modern train control, see Intertech Rail’s article Railway Signaling Systems.

Where Relays Still Matter

Digital technology now runs most of what happens on a railway, but the heartbeat is still mechanical. Fail-safe relays remain essential because they don’t depend on code or connectivity. They follow physics, not algorithms.

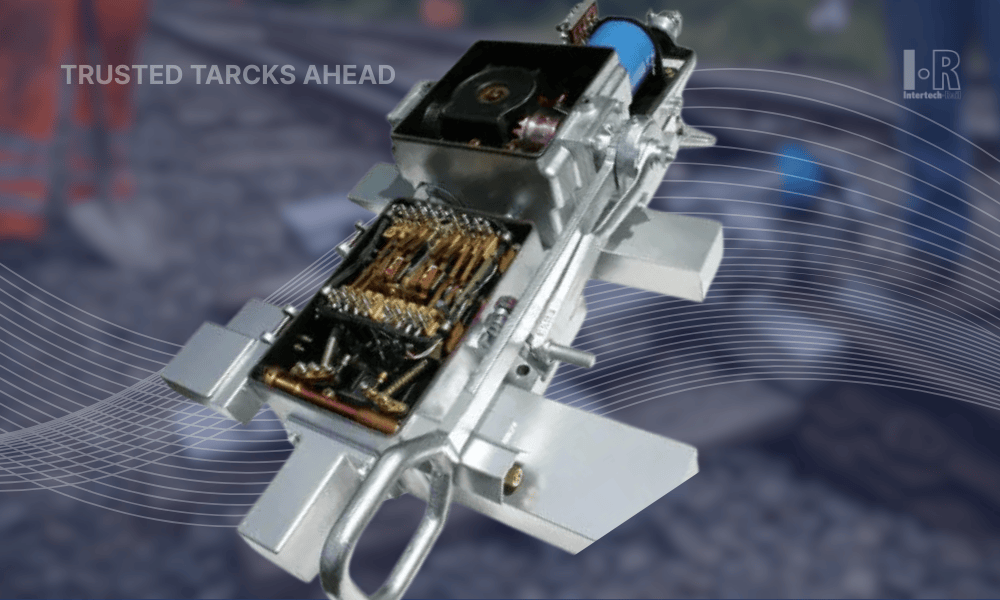

A

relay doesn’t crash. It doesn’t freeze or reboot. It simply obeys its design: open when uncertain, closed when safe. That’s why the oldest technology in signaling is also the most trusted. Behind every green light and safe stop lies a chain of relays that decide, instantly, silently, and correctly, what’s safe and what isn’t.

Standards That Keep the World Aligned

Railway safety doesn’t belong to one country or company. It runs on

global standards, rules, and certifications that define how safety-critical systems must behave. Standards like

EN 50126,

50128, and

50129

guide every layer of design, from hardware logic to software validation.

From SIL requirements to cybersecurity, safety drives innovation. These frameworks ensure that as signaling gets smarter, it doesn’t get riskier. They make sure every new technology, sensor, relay, and digital interlocking fits into a system that has proven it can fail safely. Compliance isn’t paperwork; it’s engineering accountability.

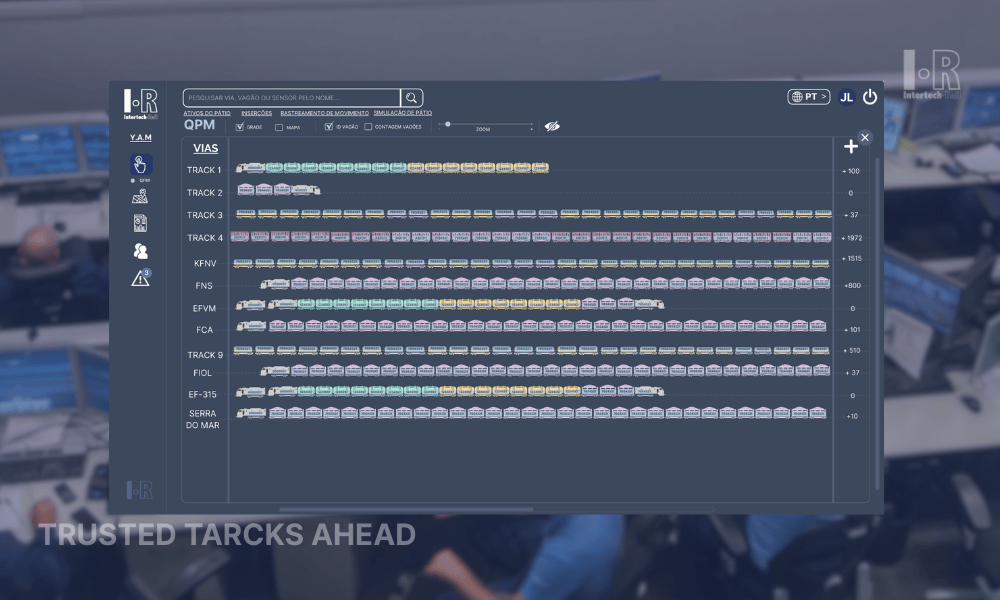

Intertech Rail’s Role in Compliance and Reliability

Intertech Rail's fail-safe relay

designs meet the most demanding global standards and have been tested across harsh environments, vibration, temperature, voltage spikes, and electromagnetic interference.

Each relay represents decades of refinement and field experience. From urban metros to heavy freight corridors, these systems carry the same promise: consistent performance when failure isn’t an option.

Beyond the relays themselves, Intertech Rail’s engineering teams support operators through audits, configuration, and documentation, ensuring that every installation meets both technical certification and operational reliability.

Redundancy as a Design Habit

Reliability in railway safety isn’t about eliminating failure. It’s about preparing for it. Systems are built with parallel circuits, backup logic, and physical separation, so a single fault never compromises control.

This philosophy extends from the smallest relay to the entire signaling network. Every point of failure has a partner watching its back. That’s not luxury; it’s survival in a system that moves lives and cargo daily.

The same philosophy applies to physical infrastructure. As noted in Intertech Rail’s article

Railway Fastener Technology, durable materials and robust connections are key to long-term safety in railway environments.

Safety in the Digital Era

As railways adopt automation and digital interlockings, safety is learning a new language. Cybersecurity now stands beside voltage tests and insulation checks. Data networks carry signals once moved by copper wires. The challenge isn’t replacing old systems; it’s protecting new ones with the same reliability. The fail-safe principle doesn’t vanish with progress; it simply adapts.

Looking Forward

The railway of the future will speak in code, but its heart will still click like a relay. Safety won’t be redefined; it will be reinforced by smarter tools and stronger standards. Because no matter how advanced the system becomes,

fail-safe design remains the anchor of trust. It’s the promise that when everything else fails, the railway still chooses safety.

Image Source: creativecommons / IntertechRail