Composite Materials in Railway Applications: Lightweight Solutions for Enhanced Performance and Sustainability

Introduction to Railway Composite Materials

You can tell a lot about a train by the way it sounds when it leaves the station. The old ones used to groan, metal against metal, heavy and slow. The new ones glide. Lighter, quieter, cleaner. That’s not luck. That’s materials catching up with imagination.

Composite materials are shaping the future of railway engineering. They’ve crept into the industry one panel, one bogie cover, one cabin wall at a time. Carbon fiber, resin, fiberglass, and pieces that seem fragile become stronger together. That mix is changing how railways think about design and weight.

Why Lightness Matters

Weight is the hidden tax of every train. More weight means more drag, more energy, and more wear on the rails. Engineers learned long ago that cutting mass isn’t vanity, it’s efficiency.

Lightweight design improves energy efficiency and durability.

A carbody that’s a few tons lighter burns less fuel, hits fewer maintenance stops, and saves thousands over its lifetime. FRP and carbon fiber aren’t fashion trends; they’re the reason trains last longer and cost less to move. It’s simple math, but it reshapes the whole network.

How Composites Changed the Game

There’s a quiet confidence in composites. They don’t rust. They don’t scream when the temperature drops. They flex, absorb, and recover. Engineers can decide how stiff or soft a panel should be, how it reacts to force or vibration. And now, they’re not just strong, they’re smart. Inside those layers, sensors can live and work without anyone seeing them. The skin of a train becomes part of its memory.

Smart Composites and Embedded Sensing

Composites are changing from structural materials into data sources. They can host embedded sensors that quietly track stress, strain, and thermal shifts, turning what was once static into something that learns.

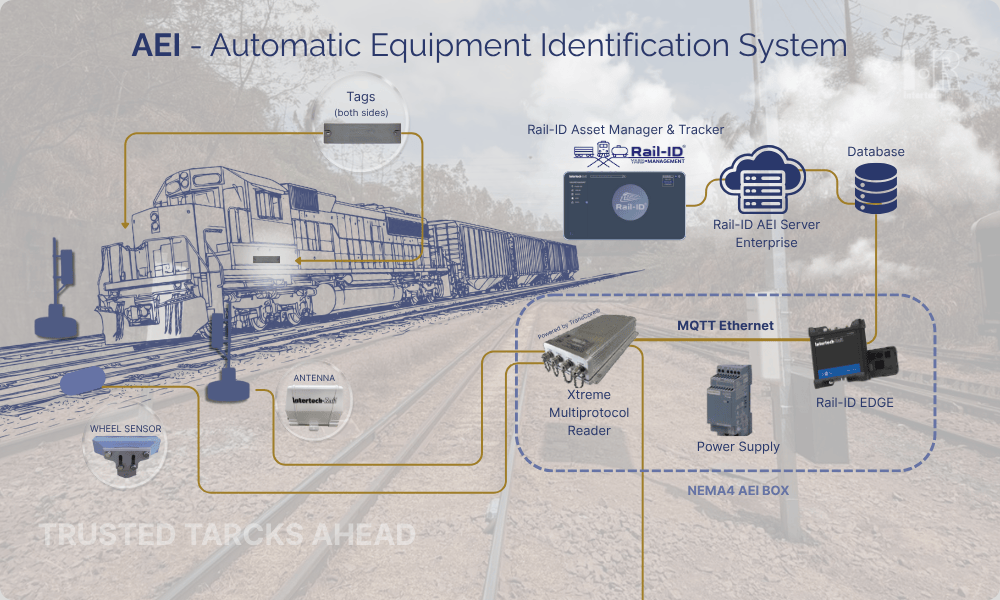

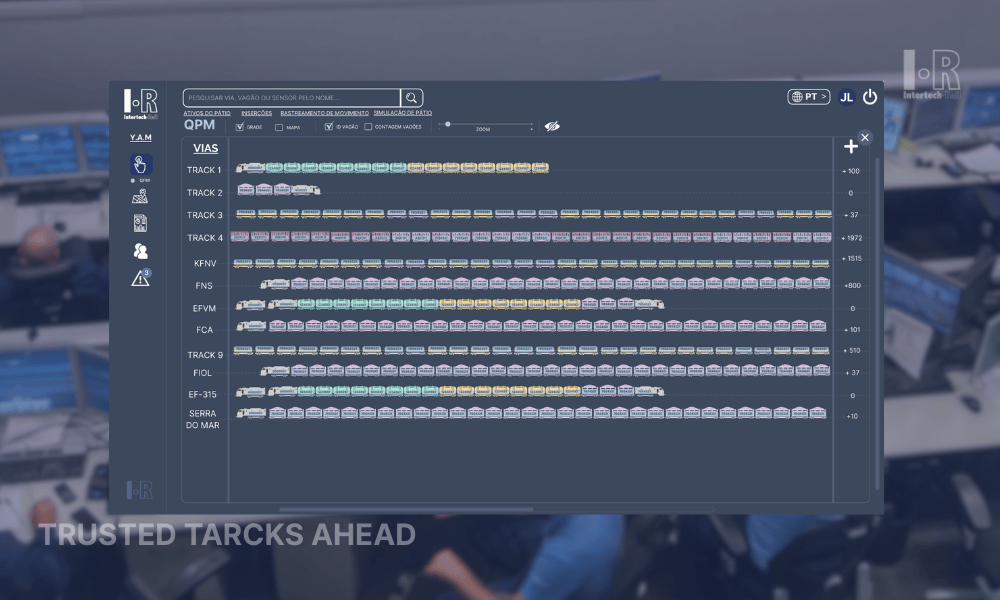

That concept already lives within Intertech Rail’s

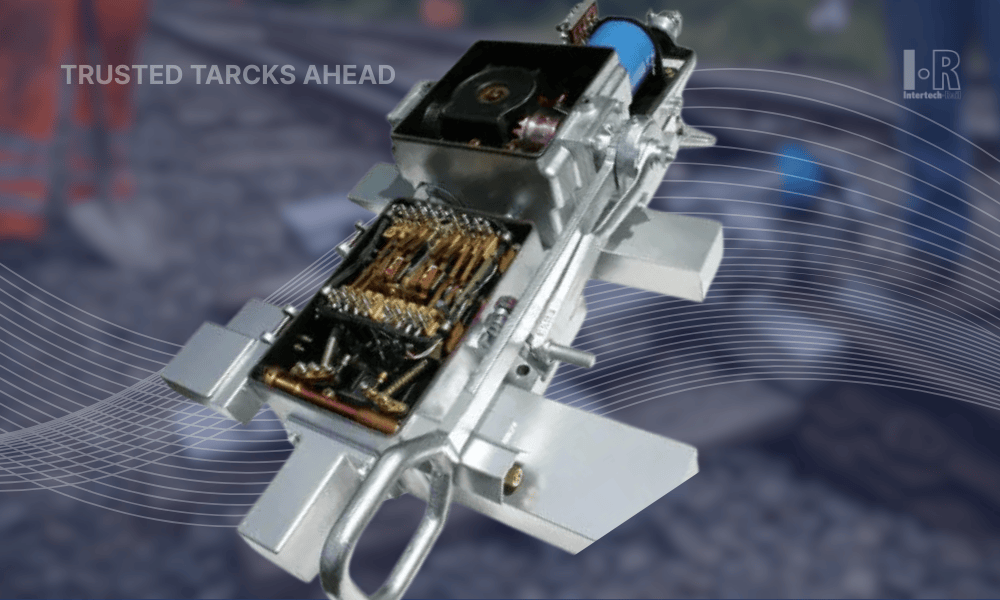

Rail-ID® and AEI System, which integrates field antennas and data modules to identify and monitor rolling stock in real time. The same philosophy, sensing from within, now extends to the materials themselves, where smart composites make every surface part of the network’s awareness.

Extra content:

The same integration philosophy is already visible in Intertech Rail’s monitoring solutions, as shown in

Enhancing Rail Logistics, where field sensors and RFID systems create a digital reflection of railway operations.

Where They Work Best

Composite parts now cover more ground than ever, underframes, fairings, door systems, and interiors. Freight wagons use lighter FRP components to reduce axle load. Bridges and sleepers made from glass-reinforced polymers are finding their place where corrosion once ruled.

Even inside, the difference shows. Less noise, better insulation, smoother surfaces. It’s the kind of progress passengers notice without knowing why.

The Other Side of Progress

Nothing’s flawless. Composites take longer to build, cost more up front, and don’t weld like steel. Repairs need skill. Recycling is still finding its rhythm. But engineers adapt, we always do.

New fibers, cleaner resins, faster curing times, all signs that the industry is learning. Sustainability isn’t a checkbox anymore; it’s part of the drawing board.

The Road Ahead

The next wave of rail innovation won’t be about faster engines; it’ll be about smarter materials. Structures that think, respond, and record their own history. Materials that act less like shells and more like living systems.

Because strength isn’t just about resisting force anymore. It’s about knowing when that force arrives. And that’s what makes this shift so powerful: the railway of tomorrow won’t just move people. It’ll understand itself.

Image Source: © Trackopedia / © IntertechRail