Railway Corrosion Protection: Advanced Coating Systems and Prevention Strategies for Infrastructure Longevity

Understanding Railway Corrosion Challenges

Corrosion doesn’t announce itself. It hides in plain sight, a small bubble under paint, a faint orange mark on a bolt, a dull patch on the rail base. Ignore it once, and it spreads. That’s how it always starts.

Corrosion protection is vital for the longevity of railway infrastructure. Steel doesn’t forgive moisture, and railways live surrounded by it. Over time, even the strongest structure will lose the fight if we don’t build with that truth in mind.

Why It Matters

No other industry pushes steel this hard. Railways mix vibration, current, water, and salt, the perfect recipe for corrosion. The underside of the rail collects standing water, fasteners trap dust and grease, and the constant flexing of steel opens microscopic cracks where rust begins its slow work.

The damage doesn’t happen overnight. It’s quiet, invisible, and steady. When it shows, it’s already expensive. Prevention isn’t a side task here; it’s the main defense keeping everything running.

Building the Shield

Every bit of protection starts before the first brush of paint. Surface prep, clean metal, smart design to keep water moving away, that’s the groundwork. Coatings come next, each layer doing its part.

Advanced coating systems enhance safety and reduce costs. Zinc primers handle sacrifice; epoxy bonds to the steel; polyurethane seals against heat and light. Done right, they form a barrier tough enough to take years of punishment.

On bridges, hybrid ceramic coatings have held back saltwater and UV for decades. On the rails themselves, protective layers stop corrosion from creeping along the base where moisture always lingers. The difference between a coating and a cover? One just hides rust; the other prevents it.

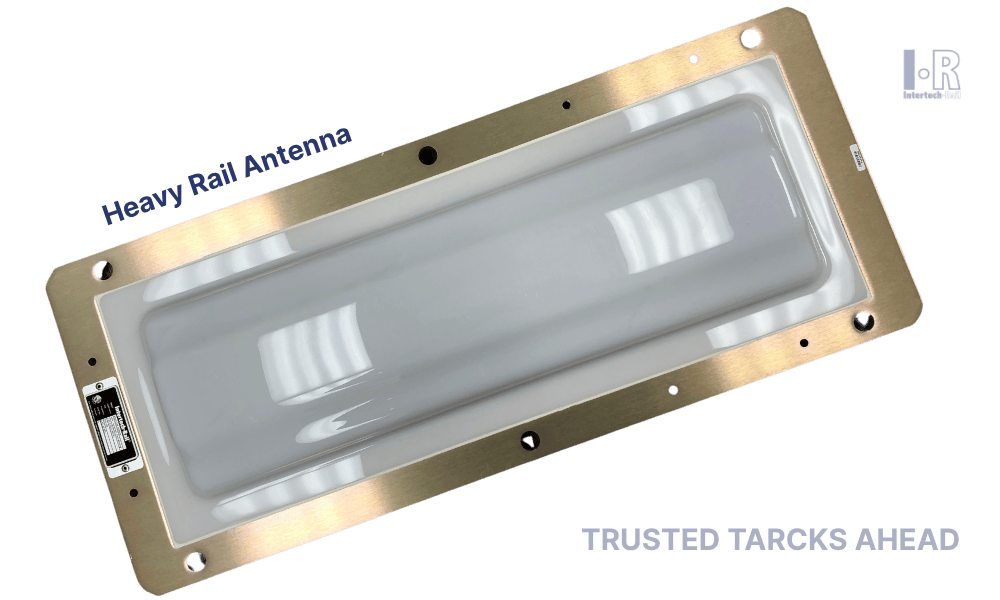

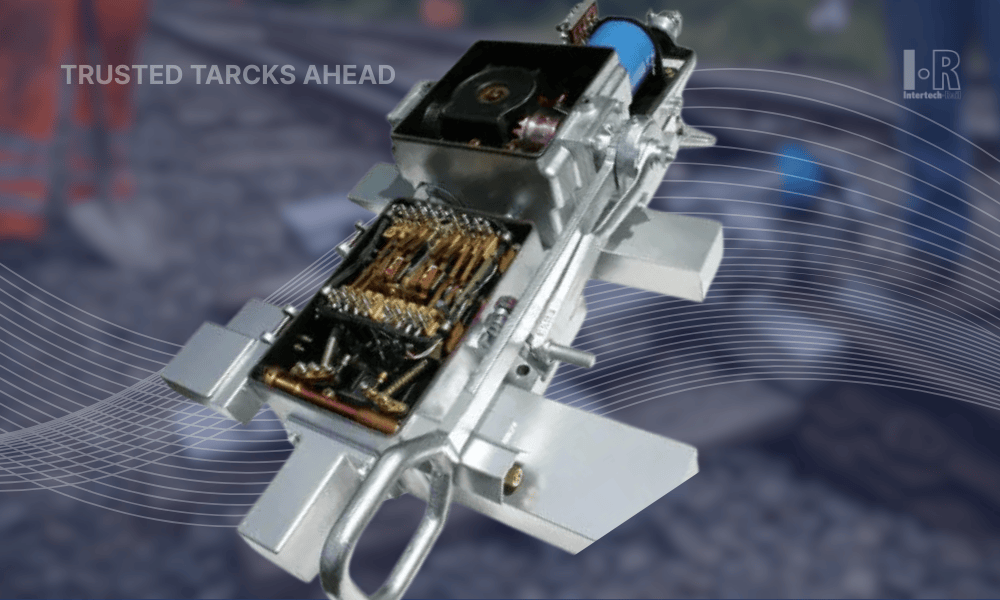

Intertech Rail’s Heavy Rail Antenna is a clear example of corrosion-resistant engineering in action. Designed for undercarriage installation, its rugged, weather-sealed enclosure resists vibration, moisture, and chemical exposure, exactly the kind of environment where corrosion normally wins. That durability not only protects the electronics inside but also extends the service life of critical AEI components, showing that corrosion control goes beyond coatings; it’s built into the hardware itself.

Extra content: Proper water control is just as critical as protective coatings. For more on drainage design and its role in long-term track stability, see Intertech Rail’s article

Railway Drainage Systems.

Modern Coatings, Smarter Chemistry

Today’s coatings are no longer simple paint. They’re engineered materials designed to flex, bond, and protect at the molecular level.

Surface blasting ensures adhesion. Zinc or aluminum primers go first, then barrier layers, then topcoats for sunlight and abrasion. In harsh zones, nano-ceramic films and self-healing coatings push the lifespan even further. When a crack appears, they release inhibitors to stop corrosion in its tracks. It’s quiet chemistry, invisible but powerful.

A System, Not a Surface

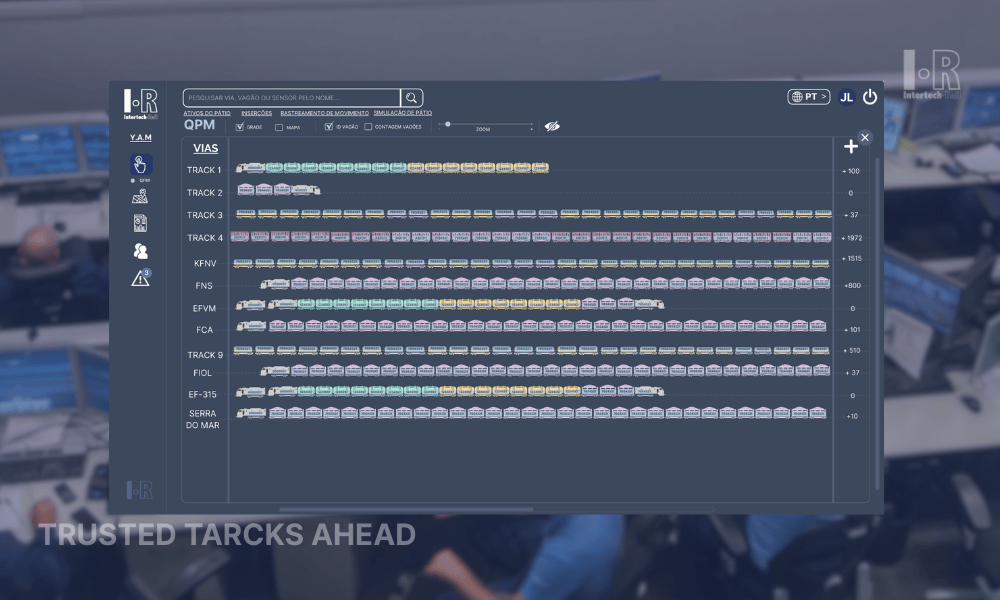

Corrosion isn’t just a matter of metal. It’s about design, climate, grounding, and drainage. That’s why the best protection now works as a system, sensors, data, and coatings all playing their part.

Maintenance teams log every inspection, coating batch, and environmental reading. Over the years, those records turn into a story of what works and where it fails. It’s not about repainting, it’s about learning.

Looking Forward

Future railways won’t wait for rust to show; they’ll see it coming. Sensors will talk to maintenance systems, coatings will adapt to weather and wear, and decisions will come from data, not guesswork.

The hardware behind those systems must last just as long, with equipment that is built for endurance, sealed, weather-proof, and ready for the harshest environments. In the end, protection isn’t about perfection; it’s about persistence.

Image Source: © Freepik / © IntertechRail