Railway System Obsolescence Management: Strategic Planning for Fail-Safe Relay Lifecycle and Technology Evolution

How Railways Plan for the Systems That Outlive Their Era

Anyone who has handled signaling equipment older than themselves knows that railways rarely discard technology quickly. Much of the infrastructure still in service was installed back when drawings were done by hand, and the idea of digital monitoring was only a theory.

But time does not pause for the industry. Equipment ages, suppliers disappear, and a relay that once had three replacement options becomes a rare item stored in a drawer “just in case.”

Obsolescence is not a sudden event. It is a slow shift in the background, felt first by maintenance teams and later by planners who need to make strategic decisions.

Understanding Obsolescence in Railway Systems

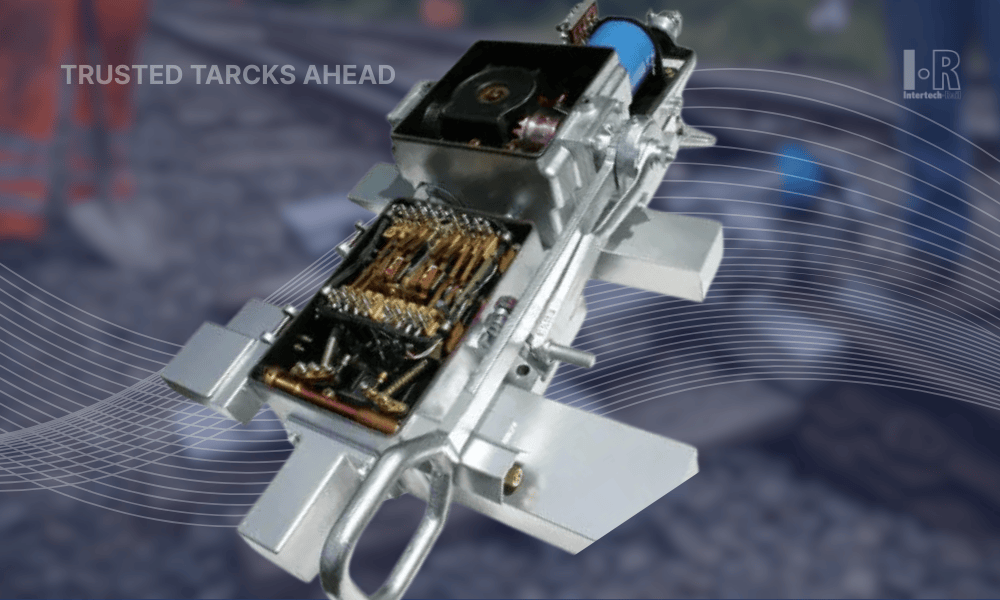

Obsolescence shows up in many ways: components no longer manufactured, materials that change over time, new interfaces that cannot link to older logic, or standards that outgrow the systems still in operation. Fail-safe relay systems, in particular, reveal this tension. They work for decades, but technology around them moves on, sometimes leaving the relay untouched but affecting everything connected to it.

Component and Technology Obsolescence

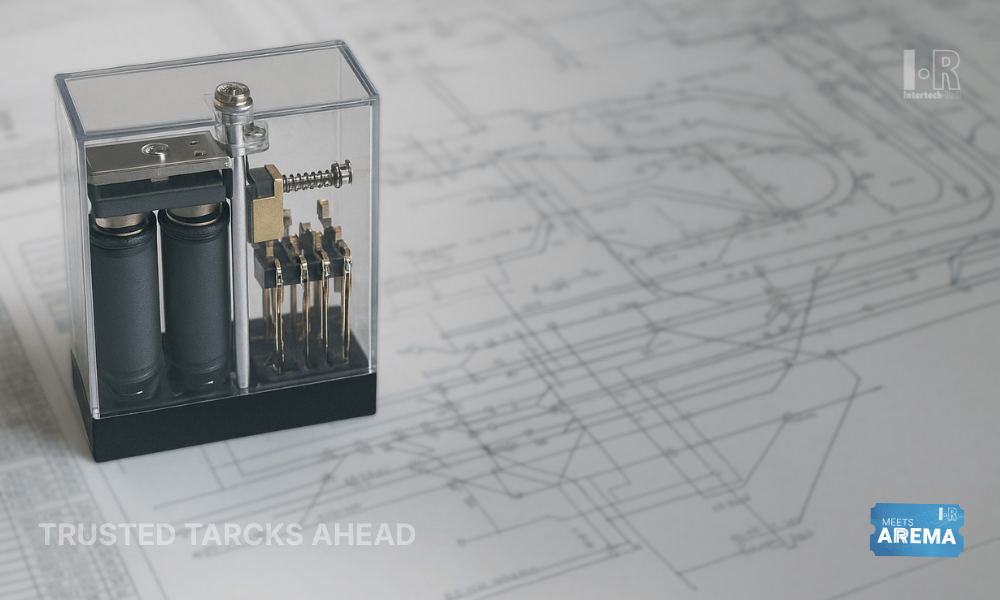

Component obsolescence is often the first warning sign. A coil specification changes, a supplier discontinues a contact material, or a particular tool needed for adjustment is no longer produced. These are small shifts, but they matter because relay systems depend on consistency. A slightly altered replacement part may behave differently under heat or vibration, even if the datasheet looks similar.

Technology obsolescence arrives more quietly. New signaling architectures introduce data channels, diagnostic layers, or hybrid modules that the older system cannot interpret. The legacy equipment still works, but it no longer fits naturally within the wider network. Railways carry this tension for years because the system works, until it suddenly does not.

Obsolescence Management Strategies

Good obsolescence management starts long before equipment becomes hard to find. It is a mix of planning, inventory awareness, and system knowledge that rarely sits with one department alone. The key is recognising when a device is beginning to approach the edge of its lifecycle and deciding what that means for the rest of the network.

Before we go further, the following list brings together Intertech Rail’s key articles on railway relays, as well as our relay product portfolio.

Proactive and Reactive Solutions, System Migration

Proactive Strategies

Proactive work feels tedious at times, but it saves entire projects later. Teams map out which relays still have active suppliers, which ones are drifting toward retirement, and where the network depends on items that already show availability gaps.

This planning often includes building small stock reserves, qualifying alternative parts, or updating documentation to reflect what is actually installed rather than what was installed originally.

Reactive Strategies

Even the best plans meet reality. Sudden failures, unexpected supplier changes, or a spike in demand from parallel industries can disrupt an entire maintenance cycle.

Reactive strategies come into play when a network must support an aging subsystem without the luxury of replacing it immediately.

Engineers adapt by redesigning surrounding circuits, introducing monitoring layers to catch failures earlier, or selectively upgrading only the most vulnerable elements.

System Migration

Eventually, every legacy system reaches a point where keeping it alive costs more than transitioning away from it.

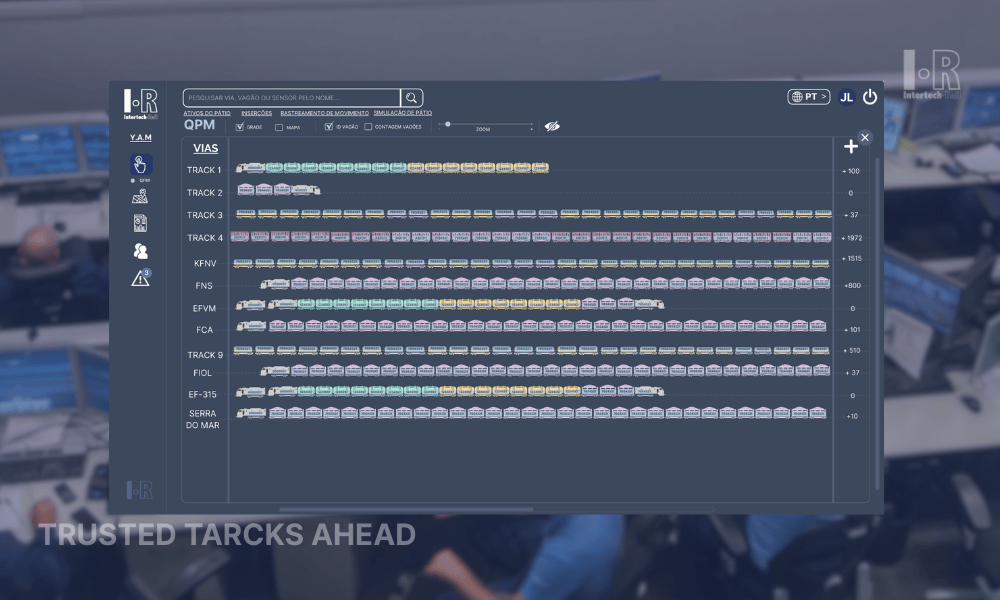

System migration is rarely a clean swap. More often, it is a staged process: a hybrid installation where modern diagnostic tools sit beside older relays, or where a digital interface allows new equipment to supervise legacy logic without replacing it outright.

Railways prefer these gradual transitions because they avoid service interruptions and respect the reliability built into the older hardware.

Obsolescence management is not just about replacing parts. It is about recognising how long each component can be trusted and how the surrounding system must adapt as technology changes.

By combining proactive planning, thoughtful reactions to unexpected gaps, and carefully planned migration paths, railways protect both their heritage and their future. In a network where equipment may serve for half a century, managing its lifecycle becomes as critical as designing it in the first place.