Railway Drainage Systems: Engineering Solutions for Water Management and Track Stability

Fundamentals of Railway Drainage Engineering

You never really notice a good drainage system, not until it fails. One night of heavy rain is enough to show how much damage standing water can do to a railway. Ballast turns soft, sleepers start to tilt, and before long, geometry goes off. That’s when everyone remembers how important drainage actually is.

Effective drainage ensures long-term track stability. It’s one of those quiet engineering jobs that doesn’t look impressive but decides how long your railway survives. Poor drainage means uneven settlement, corrosion, and maintenance headaches that never stop coming back.

It’s simple on paper: keep the track dry. In practice, it’s one of the hardest things to get right.

Why Water Is the Hidden Enemy

Ask any track inspector what they fear most, and it’s not heat or vibration; it’s water. It sneaks in slowly, hides beneath ballast, and starts changing the soil below. Once that happens, you’re in trouble.

Water management is critical to railway safety. Every flood, every soft patch, every slip trace back to how the water behaved. So, drainage isn’t just about moving rain away; it’s about controlling it. Slowing it down when needed, giving it a path, keeping it off the rails.

A well-designed railway drainage system works quietly. A bad one shows its mistakes fast.

What a Drainage System Really Does

Most people see ditches and pipes. Engineers see gradients, flow velocity, permeability, and soil types, all fighting for balance.

Track drainage design

is part math, part experience.

We break it into three main layers:

-

Surface drainage:

removes rain and runoff from the ballast and shoulders.

-

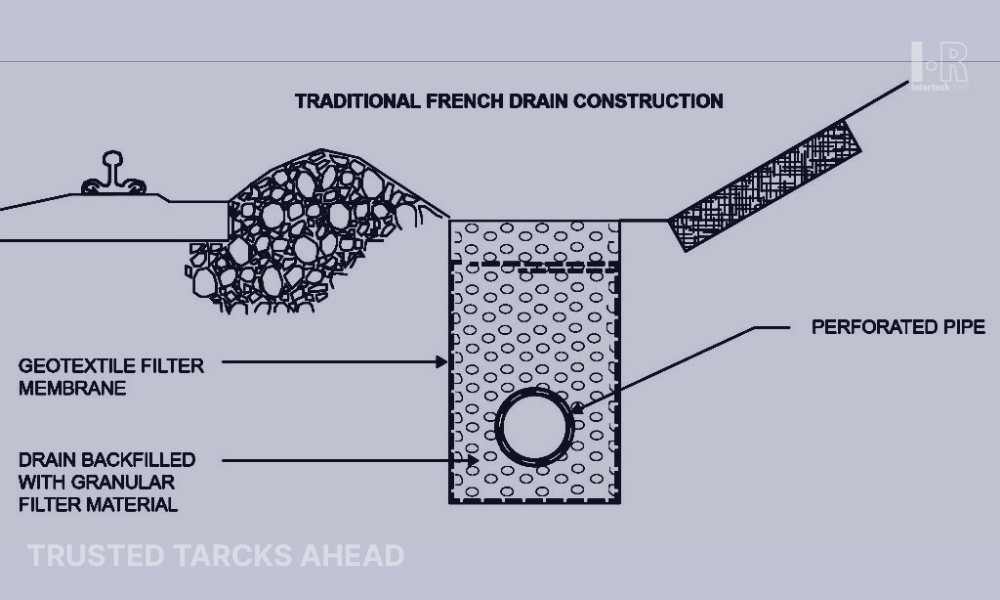

Subsurface drainage:

deals with groundwater, the slow destroyer.

-

Cross drainage:

lets water pass under embankments safely through culverts and channels.

Each system must match the landscape. In clay, you need more outlets. In sand, you manage erosion. One mistake in slope or sizing, and you’re digging the same trench next year.

Smarter Ways to Keep It Dry

A decade ago, drainage checks meant long walks and guesswork. You waited for rain, took notes, and hoped you caught problems in time. Now, we’ve got something better. Sensors.

Smart drainage systems can integrate Intertech Rail sensors, the same kind used for vibration or load monitoring. They pick up moisture changes, detect rising pressure, and even spot when a drain starts clogging. That data gets sent straight to maintenance teams before water ever hits the surface.

It’s not about replacing fieldwork; it’s about giving crews a warning before the damage happens.

For additional insight into how real-time data and sensor networks support early maintenance decisions, see Intertech Rail’s article Railway Predictive Maintenance.

Designing with the Weather in Mind

There’s no “universal”

rail track drainage design. A plan that works in Chile’s dry mountains won’t survive in Brazil’s rainy season. The goal is always the same: give the water a clear way out, but the strategy depends on where you are.

Engineers use layers of ballast, filter fabrics, and permeable pipes to guide water gently through the system. Modern ballast drainage

materials resist clogging and last longer than gravel alone. Some projects even recycle water for vegetation control or dust suppression nearby.

Good design listens to the environment. Great design keeps listening after the first storm.

For more on how environmental data supports railway safety and infrastructure planning, see Intertech Rail’s article Railway Weather Monitoring: Enhancing Safety Through Environmental Data.

Maintenance: Where It Usually Fails

Drainage doesn’t collapse overnight; it fades. Sediment builds up, roots sneak in, and a perfect slope becomes a shallow puddle. That’s why inspections matter. Regular cleaning, even small adjustments, extend a system’s life by years.

Some networks now tag each drainage section in asset management systems. They log condition grades, cleaning dates, and even rainfall data. With time, that becomes a living map of risk, one that tells engineers where to act first.

That’s how

railway water management

is supposed to work: see the issue coming, not chasing it later.

Intertech Rail’s Contribution

Anyone who has spent time working around railway tracks knows one simple truth: water always finds a way. It seeps through joints, splashes over ballast, and settles in places you don’t want it. That’s why Intertech Rail designs its equipment for the real world, not for lab conditions, but for the unpredictable, demanding environments where railways actually operate.

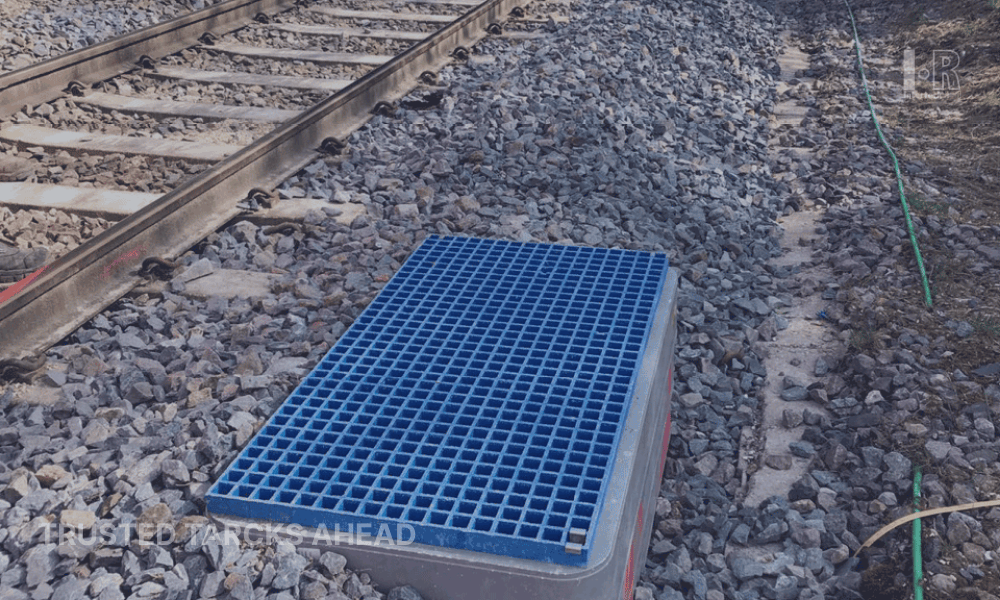

For instance, the

enclosure used for the AEI system

perfectly reflects that philosophy. It’s not fully waterproof, but it is highly resistant to water, humidity, and long-term exposure to sun, dust, and harsh weather. Built from stainless steel or aluminum, it offers strength and corrosion resistance, ensuring that the electronics inside remain protected and reliable for years of continuous service. The wheel sensor goes beyond that; it really keeps working under flood. The switch machine, like IRM23, just stops working under strong flood, but no damage after the water is gone. It simply gets back to work as if nothing happened.

In most installations, a cable splice or junction must also be sealed against moisture and potential flooding. These waterproof junction boxes are typically installed by the client, tailored to local environmental conditions, ensuring consistent performance even in challenging terrains.

This and other tailor-made solutions form the core of Intertech Rail’s engineering philosophy: building railway technology that performs reliably, rain or shine, under pressure or underwater. It’s innovation built for reality: proven, practical, and trusted where it matters most.

Looking Ahead

Drainage used to be a civil task; now it’s becoming a digital one. In the near future, all that water data will feed straight into digital twins and predictive maintenance systems. Engineers will see rainfall impact on train schedules before the storm even ends.

It sounds futuristic, but it’s already happening in pilot sites. Smart drainage, real-time monitoring, and sensor integration are rewriting what “infrastructure” means. In the end, good drainage isn’t glamorous; it’s dependable. And in railways, dependability is everything.

Image Source: © Cubis Systems / © Rail Engineer