Railway Fastener Technology

Railway Fastener Technology: Advanced Solutions for Track Stability and Infrastructure Longevity

Rails don’t stay in place on their own. They are locked to sleepers through railway fasteners, and without them, the track would not survive a single heavy haul train. Good fastening systems

spread the load, keep the gauge consistent, and maintain long-term track stability. It sounds simple, just bolts and clips, but in reality, fastening is one of the most critical layers of the whole infrastructure.

Functions and Requirements of Rail Fasteners

Every fastener has the same job: connect the rail to the sleeper while absorbing vibration and load. But the requirements change with speed, axle load, and even climate. Too loose, and the gauge spreads; too stiff, and forces travel straight into the track bed. That is why engineers often compare elastic vs. rigid fastening

to decide what works best for each line.

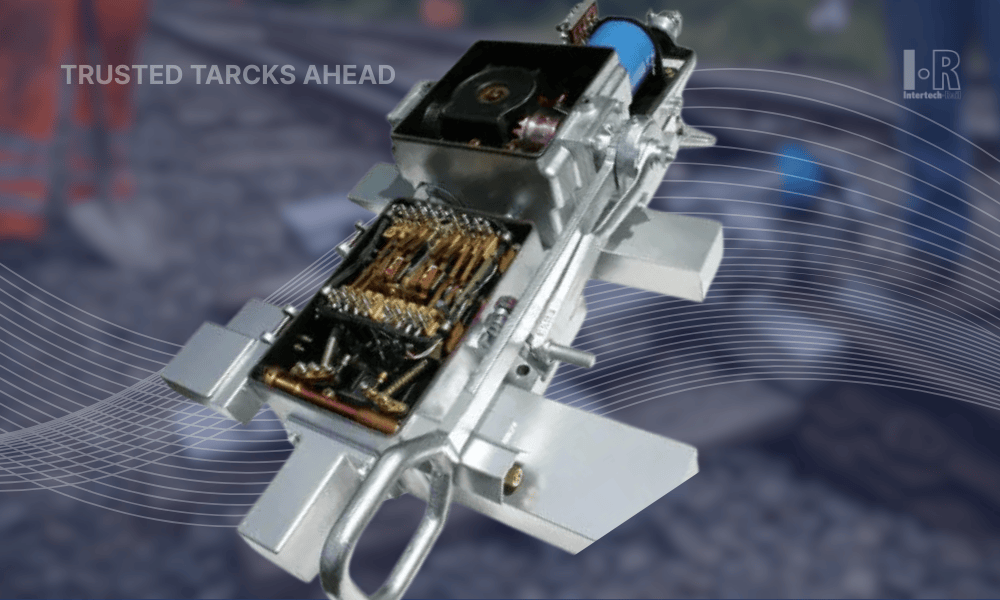

Types of Fastening Systems

On concrete sleepers, elastic clips dominate. Wooden sleepers may still use bolts or screws in some regions. Systems like Pandrol

or Vossloh

became industry standards because they combine ease of installation with reliable performance. These brands are not just products; they represent decades of incremental improvement in advanced fastening solutions

that respond to both heavy freight and high-speed needs.

Material Science and Engineering

Fasteners look small, but the material choice makes or breaks their lifespan. Steel alloys resist fatigue and corrosion, while polymer pads reduce vibration and extend rail life. The combination defines how long the fastener will hold its grip before replacement. In coastal or desert environments, engineers must pay special attention to coatings and insulation.

Installation and Quality Control

Fasteners are only as good as the crew that installs them. Torque levels, alignment, and inspection intervals all determine if the system performs. Maintenance teams rely on quality assurance and testing methods

to verify that clips, bolts, and pads are within spec. When one fastener loosens, the rail shifts, and the entire geometry suffers. Anyone who has walked a line after a derailment knows how often the root cause is tied back to a neglected fastener.

Strong rails require more than sleepers and ballast. Railway fasteners

are the invisible glue of the track, ensuring stability mile after mile. With proven systems such as Pandrol and Vossloh, the industry has moved toward advanced fastening solutions

that adapt to different conditions. Careful selection between elastic vs. rigid fastening, supported by strict quality assurance and testing methods, keeps infrastructure safe, durable, and ready for the next generation of railway operations.