Train Bogie Systems

Train Bogie Systems: Design Principles, Components, and Modern Innovations for Enhanced Performance

Understanding Train Bogie Fundamentals

The bogie is a strange thing. Hidden under the car body, people rarely notice it, yet everything depends on it. Train bogie systems

carry the load, steer through curves, and absorb shocks that the track keeps throwing at the wheels. Without a good bogie design, you feel it right away—rough rides, high wear, even safety concerns. Ask any operator, and they will tell you: the bogie decides ride quality and passenger comfort

more than the seats do.

Bogie Functions and Design Requirements

At its simplest, the bogie just keeps wheelsets

in line with the rails. In practice, it is far more complicated. The forces on a curve, the constant vibration, the uneven track, all of that must be handled without losing stability. That is why suspension systems

became the focus. Springs, dampers, and linkages, all adjusted to balance stiffness and flexibility. Too soft, and the car sways. Too hard, and both track and wheels suffer. There is no single formula; every network tunes it differently.

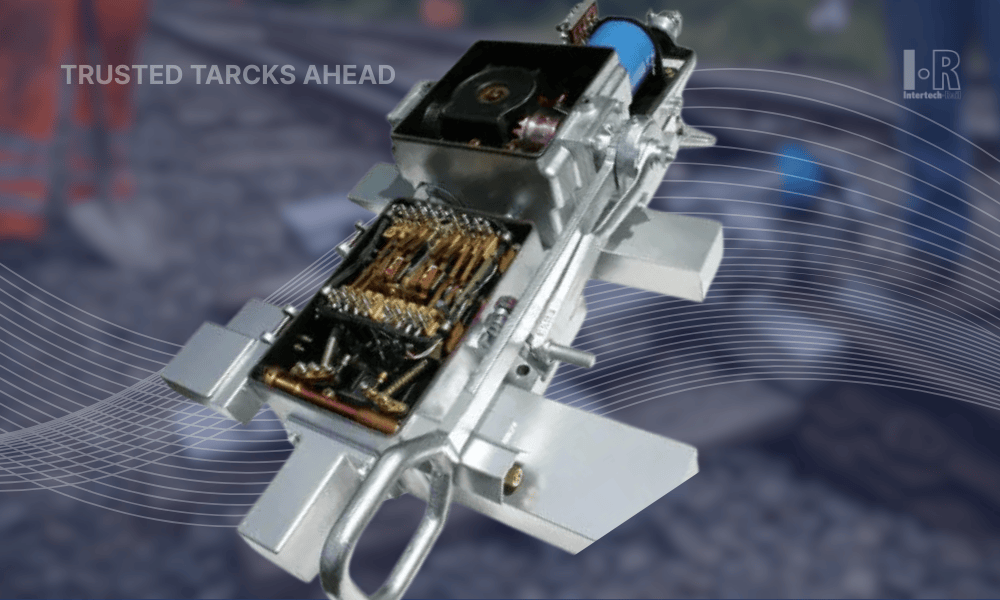

Key Components and Subsystems

Look closer and you see how many parts interact. Primary and secondary suspension systems

work together to manage vertical and lateral loads. Bearings reduce friction so wheelsets run freely. The bogie frame holds brakes, and in powered versions, traction motors as well. One weak component pulls the rest down. Workshops know this too well: if a bearing overheats, soon the suspension feels the stress, and maintenance teams end up pulling the whole bogie apart.

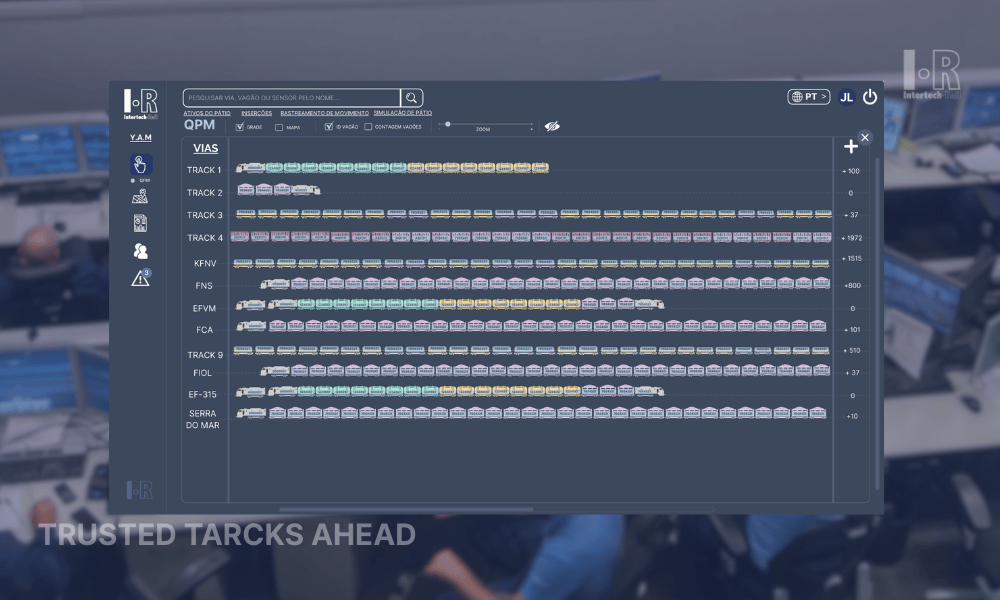

Modern Bogie Technologies and Innovations

The trend now is lighter and smarter. Designers are replacing old heavy steel with lightweight materials

such as aluminum or composites. It saves weight, reduces energy consumption, and cuts down on track wear. But materials are only part of it. The real shift comes from smart bogie technologies. With integrated sensor systems, engineers see real-time data: heat, strain, vibration. Feed that into predictive maintenance models, and suddenly the bogie is not just carrying the train, it is talking back, warning before failure.

Performance Optimization and Maintenance

From the passenger’s view, the bogie is invisible, but they judge it every trip. Smooth ride? Quiet curve entry? That is bogie work. For operators, the concern is cost and uptime. Better bogie design, the use of lightweight materials, and continuous monitoring all reduce surprises. In the past, failures showed up during service runs. Now, with data and sensors, issues are flagged early, less downtime, more reliability, and most importantly, better ride quality and passenger comfort.

The bogie may be hidden, but it runs the show. Train bogie systems link the vehicle to the track; nothing else works without them. With new suspension systems, smarter sensors, and predictive maintenance, bogies are no longer just mechanical frames. They are evolving into platforms that carry weight, absorb shocks, and also inform operators how to keep the fleet safe and efficient. That is the future: a bogie that not only supports the train but helps maintain it too.