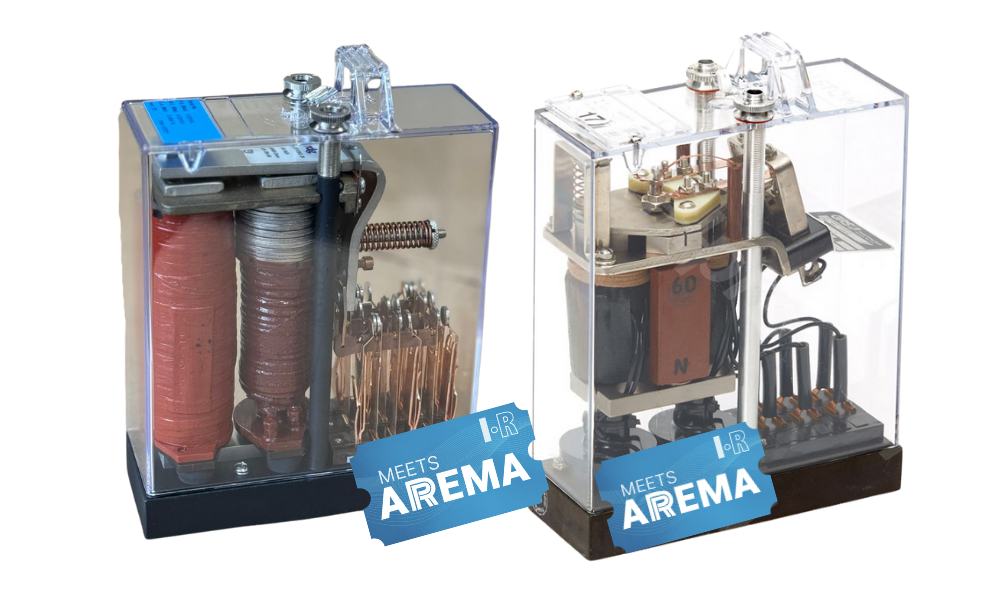

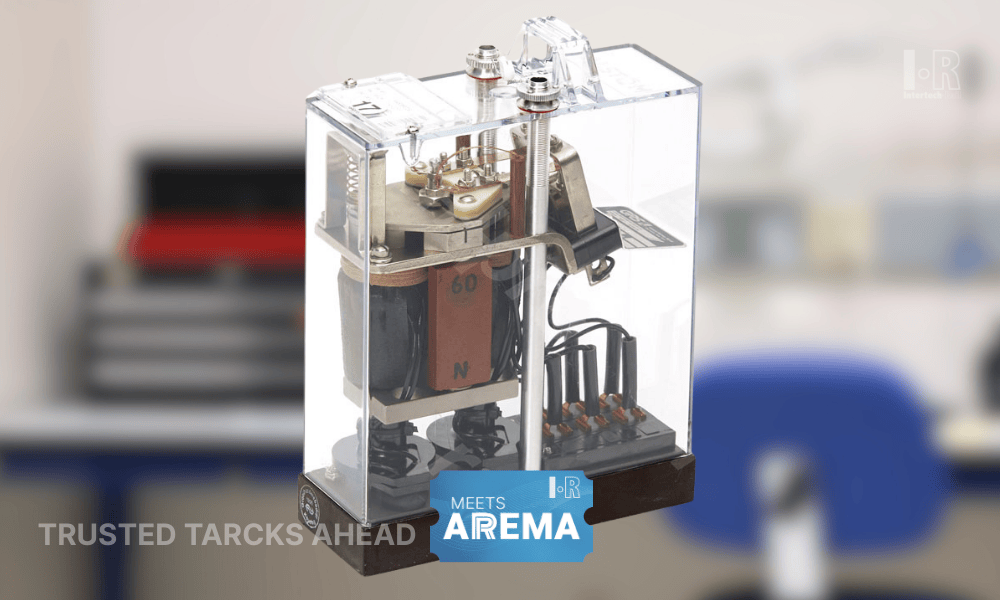

Railway Relay Testing Procedures: Comprehensive Testing Protocols for Fail-Safe Signaling Systems

Fundamentals of Railway Relay Testing

Railway signaling only works because every component in the chain behaves exactly as expected. Among all those components, relays remain one of the few devices whose mechanical movement still determines whether a route is safe. Because of that, the testing process for these relays is far more than an inspection; it is the verification that the system’s logic is trustworthy.

A relay must demonstrate consistent electrical and mechanical behavior before it is approved for service. Engineers look for stability under load, predictable motion of the armature, and endurance against the field conditions that wear equipment down over time.

Testing Requirements for Safety-Critical Relay Systems

For relays classified as safety-critical, validation focuses on how the device responds when exposed to stress factors commonly seen in signaling environments:

- sudden changes in voltage

- long periods of vibration

- temperature variations across seasons

- repeated operation cycles

Any relay that cannot maintain identical behavior through these conditions is removed from consideration.

Vital Relay Testing Standards and Procedures

Vital relays follow a detailed routine rooted in well-established standards such as AREMA and CENELEC. This routine normally includes:

- measuring contact resistance and travel

- checking both pickup and dropout values

- verifying insulation and dielectric strength

- observing the device during simulated failure conditions

The intention is not only to confirm proper function but to prove that the relay will fall back to a safe state if anything goes wrong.

Safety Integrity Level (SIL) Testing Requirements

Systems that require SIL classification require an additional layer of testing. Here, engineers analyze:

- the likelihood of dangerous failures

- long-term reliability trends

- repeatability of movement across hundreds of tests

- behavior under extended environmental stress

These additional steps build confidence that the relay will remain dependable across its full life cycle.

Types of Relay Tests and Validation Methods

Relay testing is divided into several categories, each one focusing on a different aspect of the device’s performance.

Functional Testing vs. Performance Testing

Functional tests verify basic operation, whether the relay opens, closes, and returns to its rest position correctly.

Performance tests explore how efficiently the relay does this, checking:

- switching time

- changes in contact pressure

- thermal drift

- mechanical consistency

This combination reveals both the expected behavior and any early signs of degradation.

Environmental and Stress Testing

Environmental tests push the relay into situations that simulate long-term exposure to the field:

- vibration along multiple axes

- shock impacts

- humidity and thermal cycling

- electromagnetic interference

If the relay shows instability here, it is unlikely to remain reliable in signaling cabinets exposed to weather and rail traffic.

Testing Equipment and Instrumentation

Accurate relay evaluation depends on rigorous measurement tools.

Automated Test Equipment for Relay Validation

Automated benches provide controlled conditions and precise measurements. They capture:

- electrical curves during pickup and release

- switching times recorded in milliseconds

- gradual changes in coil temperature

- mechanical drift after prolonged cycling

This data helps engineers detect trends that are invisible to manual inspection.

Portable Test Sets and Field Testing Tools

During field maintenance, crews rely on portable kits to confirm that relays remain within specification. These kits measure:

- coil resistance

- insulation level

- continuity of contacts

- operation at actual line voltage

It’s a quick way to identify relays that need further lab evaluation.

Advanced Testing Methodologies and Procedures

As signaling systems evolve, relay testing follows the same path, combining traditional verification with long-term reliability studies.

Contact, Insulation, Dielectric, and Endurance Testing

Each test addresses a different failure mode:

- Contact tests reveal wear and increased resistance.

- Insulation tests confirm that coil windings and metal parts remain electrically isolated.

- Dielectric tests apply high voltage to check resistance to breakdown.

- Endurance tests push the relay through thousands of operations to simulate years of service.

These methods form a complete reliability profile, ensuring that relays can maintain fail-safe behavior throughout their operational life.