Legacy Railway System Modernization: Upgrading Signaling Infrastructure with Modern Fail-Safe Technologies

Challenges in Legacy Railway System Modernization

Anyone who has ever opened an old signaling cabinet knows that modernization is rarely straightforward. Parts that look identical on paper behave differently in real life. A relay that worked flawlessly for decades may suddenly show timing drift when new hardware is added next to it. And nothing stops, the railway keeps running while upgrades happen.

The hardest part is figuring out what the old system can tolerate. Some components handle modern equipment without issues; others react poorly to small changes in voltage or noise. The drawings don't always match reality, and every route has its own set of quirks built up over the years.

Assessment of Existing Infrastructure and Compatibility

Before planning anything, engineers spend a long time checking what actually exists. Cabinets get opened, wiring is traced, measurements taken, and notes compared to documents that may or may not be up to date. Compatibility becomes the anchor for every decision.

A few questions usually decide the path forward:

- Is the existing wiring stable enough for new electronics?

- Do the current relays meet timing requirements when paired with new modules?

- Are there hidden environmental issues, heat, moisture, vibration, that will affect the upgrade?

- Finding honest answers early prevents a lot of trouble later.

Modernization Strategies and Technologies

Once the assessment makes sense, the next step is choosing how to modernize. Few networks replace everything at once; most prefer a slow transition, mixing what still works with what needs to be added.

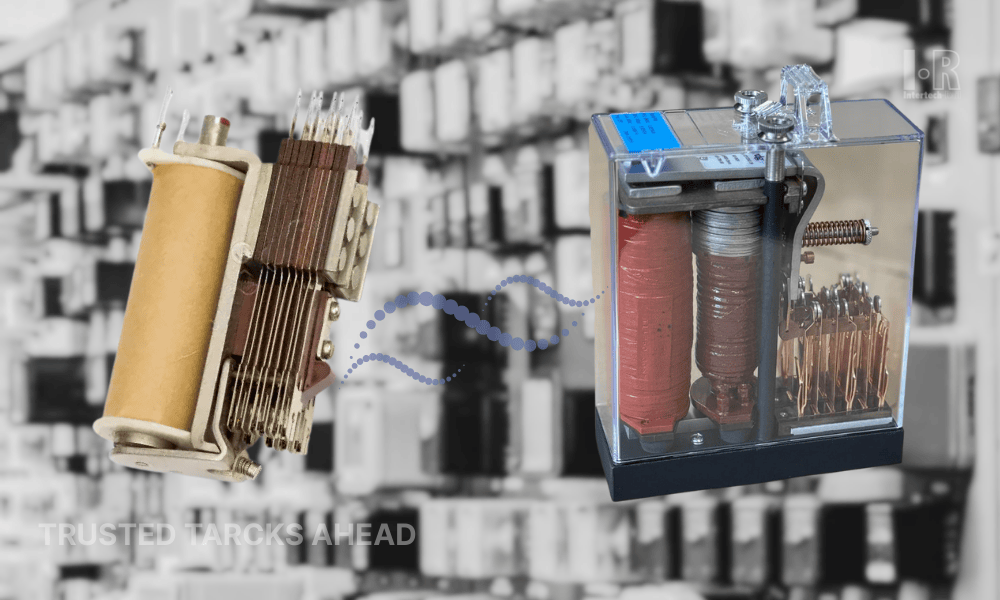

A quick note from the field: Intertech Rail offers a full lineup of signaling hardware, from Type B relays and electro-mechanical fail-safe relays to DC track circuit modules that strengthen legacy panels. Alongside that, the company maintains a growing library of technical articles on fail-safe relay design, testing, and modernization, a helpful resource for anyone working through upgrades like these.

Hybrid Systems, Smart Monitoring, and Digital Integration

A hybrid approach is the most common. The older relay logic remains in place while modern fail-safe modules handle diagnostics, data capture, and other functions the legacy system was never designed for. This lets the railway keep running, which is usually the priority.

Smart monitoring tools add another layer. Small sensors monitor parameters such as coil temperature, contact behavior, and electrical noise. These don’t change how the system works, but they give visibility into problems long before a failure occurs.

Digital integration comes next. Interfaces link the old logic with newer control systems, so data flows both ways. The railway gains modern supervision without tearing out the entire signaling backbone.

In the end, modernization is less about replacing the past and more about helping an old system work comfortably with new technology. If the upgrade respects fail-safe principles and the limits of the legacy hardware, the result is usually a network that performs better without losing the reliability it has built over the years.