RFID - BEST PRACTICE IN YARD MANAGEMENT

Rail yard management can be a complex and time-consuming task for rail operators. With thousands of railcars moving in and out of the yard every day, it can be challenging to keep track of all the moving parts. However, the use of Radio-Frequency Identification (RFID) technology can simplify the process and ensure a perfect rail yard management system.

RFID technology uses radio waves to communicate between a tag attached to an object, in this case, a railcar, and a reader. The reader then transmits the information to a central computer system, which can be accessed by the rail yard management team.

To use RFID technology effectively in rail yard management, there are several steps to follow:

Step 1: Tagging the railcars

The first step in implementing RFID technology is to tag each railcar with an RFID tag. These tags can be attached to the railcar in several ways, including bolt-on tags, adhesive tags, or embeddable tags. The tags should be placed in a location that is easily accessible for scanning.

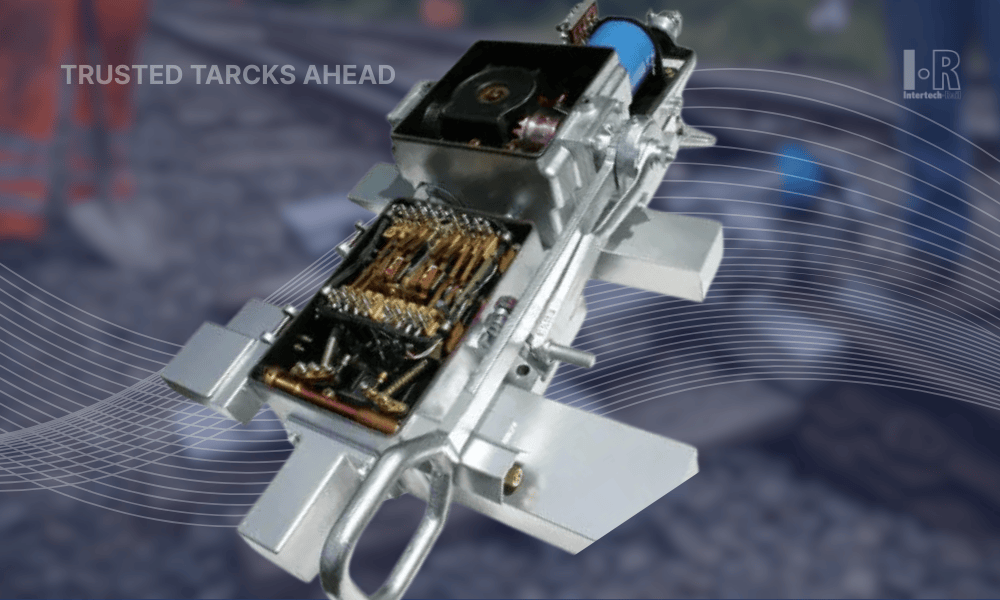

Step 2: Installing RFID readers

Once the railcars are tagged, RFID readers need to be installed in key locations throughout the rail yard. These readers should be strategically placed at points where railcars enter and exit the yard, as well as at key junctions within the yard. The readers should be connected to a central computer system that can process the data collected by the readers.

Step 3: Scanning the railcars

When a railcar enters the yard, it should be scanned by an RFID reader. The reader will then transmit the data to the central computer system, which will store the information about the railcar's location, contents, and any other relevant information.

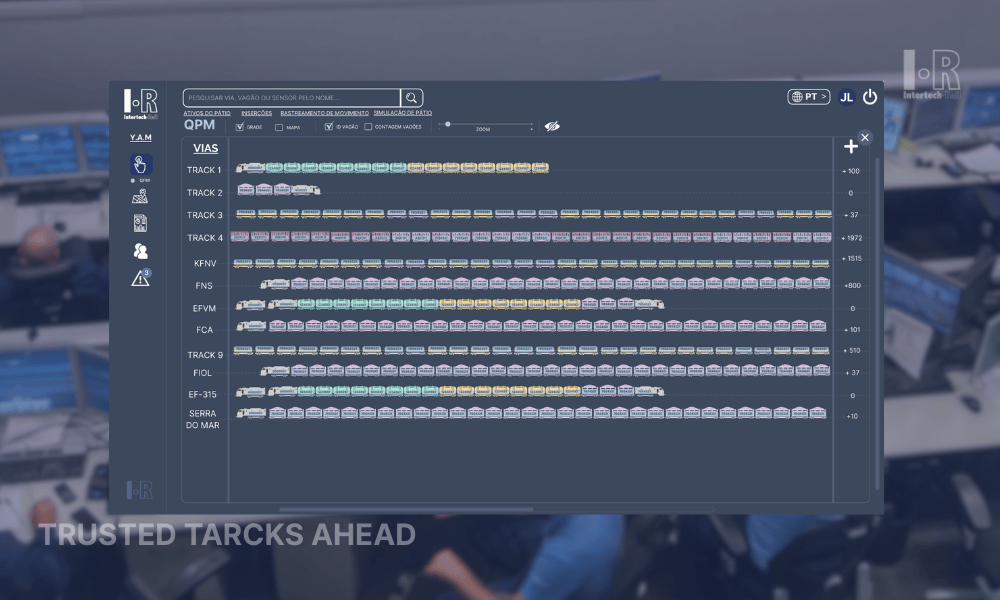

Step 4: Tracking the railcars

With RFID technology, rail yard management teams can track the movement of railcars throughout the yard in real-time. This allows them to optimize the routing of railcars, reducing the time spent waiting in the yard, and improving overall efficiency.

Step 5: Automating processes

RFID technology can also be used to automate several processes within the rail yard. For example, when a railcar is due for maintenance or inspection, the system can automatically generate a work order and notify the appropriate personnel. This helps to ensure that railcars are properly maintained and reduces the risk of accidents or breakdowns.

Step 6: Data analysis and reporting

The data collected by the RFID system can be analyzed to identify patterns and trends in rail yard activity. This information can be used to improve processes, reduce costs, and increase efficiency. Reports can be generated automatically to provide insights to management teams, enabling them to make informed decisions about the operation of the rail yard.

The use of RFID technology in rail yard management can streamline processes, increase efficiency, and reduce costs. By tagging railcars, installing RFID readers, tracking movement in real-time, automating processes, and analyzing data, rail operators can improve their overall management of rail yards. The result is a perfect rail yard management system that enables rail operators to maximize productivity while reducing costs and improving safety.