Tough Tags for Tough Tracks: Meet the Harsh Environment RFID

Tough Tags for Tough Tracks: Meet the Harsh Environment RFID

Automatic Train Control (ATC) is transforming railway operations worldwide. Bringing together safety, efficiency, and technological advancement, ATC is now a cornerstone of modern railways. In this guide, you’ll learn the fundamentals of ATC, track its evolution, explore system types, examine strategic benefits, and highlight how Intertech Rail delivers robust ATC solutions through its advanced products.

Fundamentals of Automatic Train Control (ATC)

What is ATC and How It Works

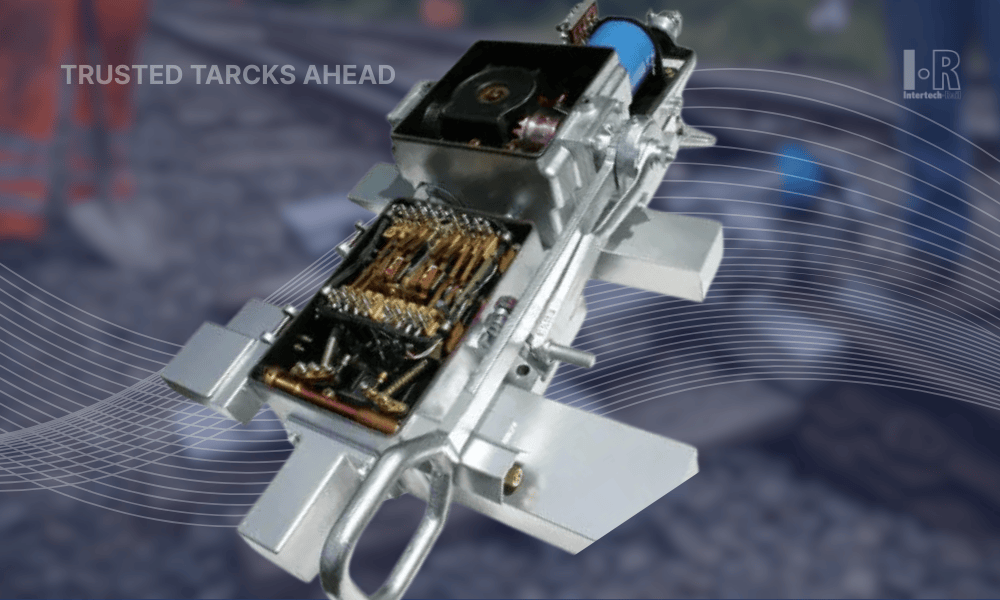

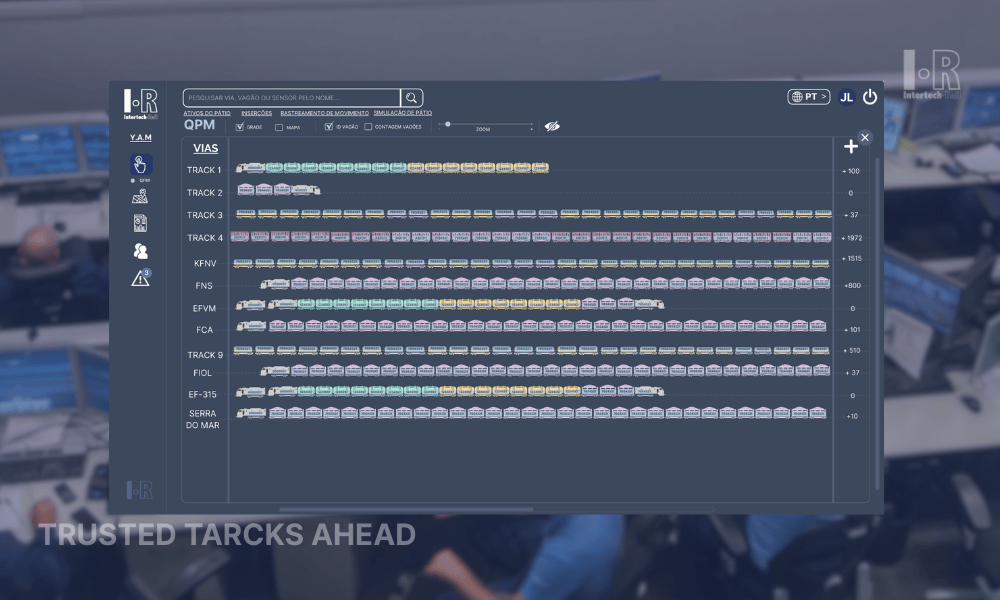

ATC is a safety-critical system that applies braking or speed control when trains exceed limits or miss signals. It typically uses trackside Tags (also known as balises) and onboard readers to relay real-time information to the train’s computer. That communication supports automatic braking, speed adjustments, and signal enforcement.

Main Components of an ATC System

- Trackside Tags/Beacons: encode vital data—speed limits, gradients, stations.

- Onboard Readers and Processors: detect Tags, interpret messages, and trigger interventions.

- Control Interface: links ATC with train control software and traffic management systems for coherent operations.

Levels of Automation in Railway Systems

Rail control spans a spectrum:

- ATP: Basic protection—safe speeds and collision avoidance.

- ATC: Builds on ATP to manage routing, spacing, and traffic.

- ATO: Enables fully automatic driving with optimized braking, acceleration, and energy efficiency.

Want to dive deeper into the acronyms? Take a look at ATP, ATC, and ATO Explained

– Demystifying Railway Automation

to better understand how these automation levels work together in modern rail systems.

Historical Evolution of Train Control Systems

From Manual Systems to Fully Automated Systems

Railways began with manual signaling and human-operated brakes. The first automatic systems appeared in the early 20th century, alerting drivers to upcoming signals. These evolved into digitally monitored systems with automatic speed enforcement.

Important Milestones in ATC Development

Major advancements included:

- Introduction of cab signalling.

- Development of digital ATC systems in high-speed networks like Japan’s Shinkansen.

- Integration with traffic management and communication-based train control (CBTC).

Types of ATC Systems

- Cab-Based Systems: These use onboard computing and sensors to enforce speed and braking within the cab environment.

- Track-Based Systems: These rely on physical balises and trackside infrastructure to communicate and control train movement.

- Hybrid and Integrated Systems: Modern networks often combine both approaches, using tags for safety enforcement and digital links for routing and spacing optimization.

Strategic Benefits of ATC Implementation

Why ATC Matters: Key Benefits

Automatic Train Control significantly improves rail operations. It reduces the risk of accidents by minimizing human error and preventing collisions through automated braking. With better spacing between trains, ATC increases line capacity—especially valuable in high-demand corridors. It also supports energy efficiency by optimizing driving patterns and helps lower long-term operational costs. For passengers, the result is a smoother, more reliable ride.

Intertech Rail and ATC Integration

Intertech Rail provides trackside tags and onboard readers compatible with various ATC systems, including those operating in harsh environments. Our solutions comply with SIL‑4 safety standards

and AREMA guidelines. The technology supports integration across different platforms and has been deployed in locomotive fleets globally. Components are built to withstand demanding operational conditions in both freight and passenger rail networks.

Future Trends in ATC

- Integration with ETCS/CBTC: Combining balise-based systems with continuous communication is setting new standards in global railways.

- AI‑Enhanced Traffic Management: Predictive analytics can further optimize traffic flow and energy use.

- Moving‑Block Systems: Continuous block monitoring, rather than fixed-block, can reduce headways further.

Overall, Automatic Train Control (ATC) is a strategic investment for safety-focused, high-capacity railway systems. By automating speed enforcement, optimizing spacing, and enhancing operational efficiency, ATC delivers tangible benefits to operators and passengers alike.

Intertech Rail delivers industry‑grade, SIL‑4 certified solutions—balises, readers, fail‑safe relays—designed for integration with

ATP, ATC, ATO systems

worldwide. Backed by decades of experience and compliance with AREMA standards, Intertech Rail products help rail networks transition seamlessly into the future of safe, reliable, and efficient rail transport.