Guide to Railway Relays: Types and Functions

Guide to Railway Relays: Types and Functions

Railway relays are essential components in modern railway switch mechanisms and signal control systems, ensuring safe, accurate, and reliable operations across various types of railroad infrastructure. Intertech Rail, a leading provider of automated railway technology, offers a wide range of fail-safe relays engineered to meet the rigorous demands of today’s rail switch and signaling networks.

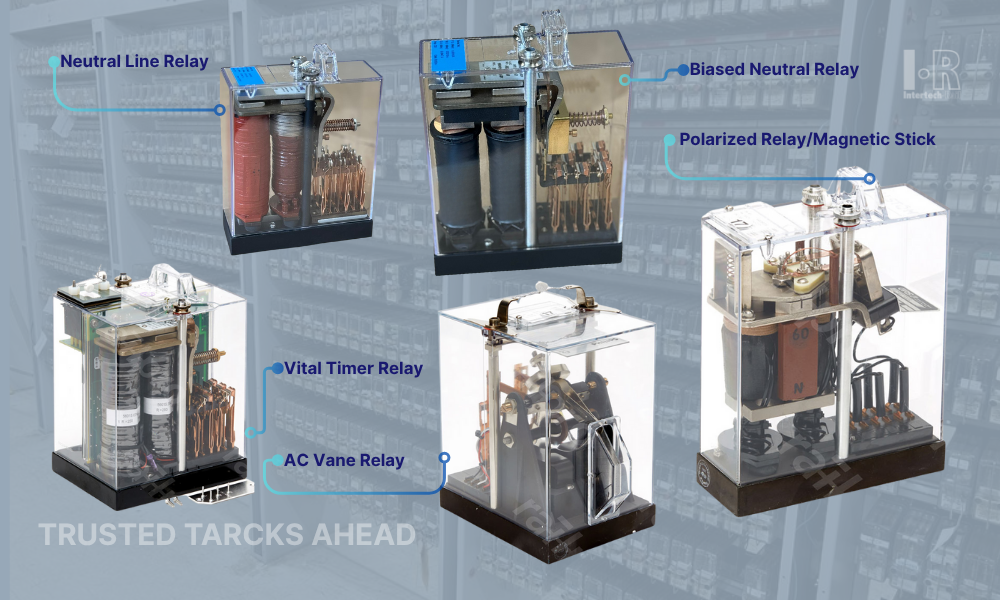

Fail-Safe Relays: Ensuring Safety Through Design

In the event of a malfunction or power failure, fail-safe relays are designed to switch automatically to a secure state. This feature is vital in railway applications where switch point rail safety and system continuity cannot be compromised. Intertech Rail’s relays use mechanical engineering principles and gravity-based design to ensure any failure triggers the safest outcome, avoiding accidents and preventing equipment damage — particularly in critical railroad switch control zones.

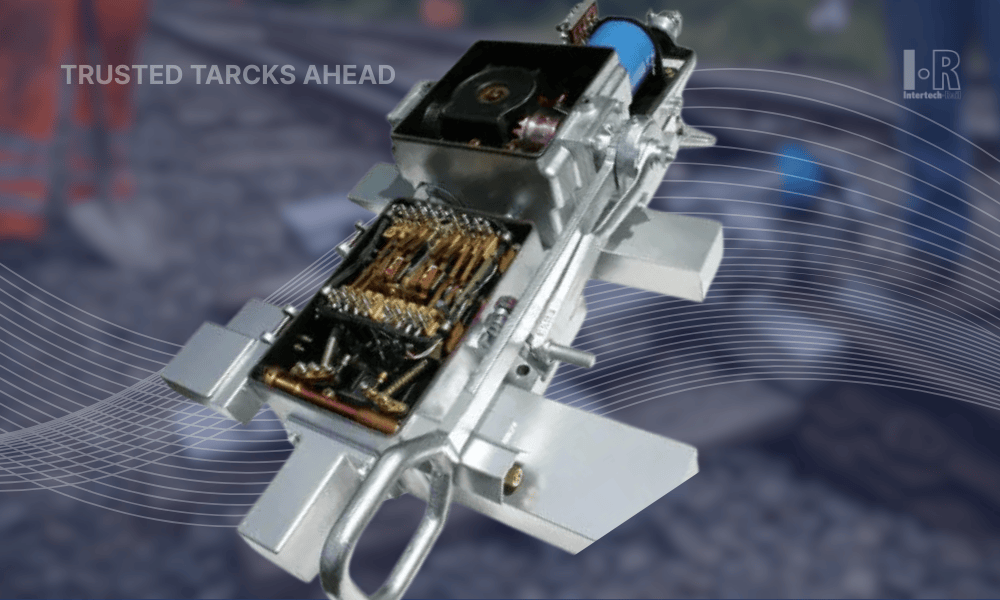

Type B Relays: Versatility and Reliability

A foundational part of Intertech Rail’s rail signaling relay lineup, Type B relays are known for their mechanical durability and wide application in railroad switch and interlocking systems. These relays feature a 0.050" front contact opening and incorporate metal-impregnated carbon-to-metal front contacts and metal-to-metal back contacts for long-term, stable performance — ideal for heavy-duty rail applications.

Key Types of Type B Railway Relays

- Biased-Neutral Relays – Respond to current direction to enable selective control in

track circuit applications.

- B1 Flasher – Controls flashing signal lights, essential in

level crossing systems.

- B1 Light-Out Neutral – Monitors for signal lamp failure to maintain

signal visibility and operational safety.

- B1 Lamp-Control – Regulates lamp circuits to ensure optimal lighting across

rail switch indicators.

- B1 Power Transfer – Ensures uninterrupted power flow across critical

railroad switch components.

- B1 Code Responsive – Interprets coded signals in complex

signal interlocking systems.

- B1 Switch-Overload Neutral – Protects

track switch mechanisms from electrical overloads.

- B1 Switch-Control – Directs

track switch alignment and safe route setting.

- B1/B2 Neutral Normal Release – Provides reliable release operations for various

switch and signaling systems.

- B1/B2 Neutral Slow-Acting – Adds precise delays where

timing coordination is required.

- B2 Code Transmitter – Sends coded signals within integrated

rail control environments.

- B2 Vane, 2 Position AC Track – Detects position in

AC-based track circuits, contributing to

accurate switch operation feedback.

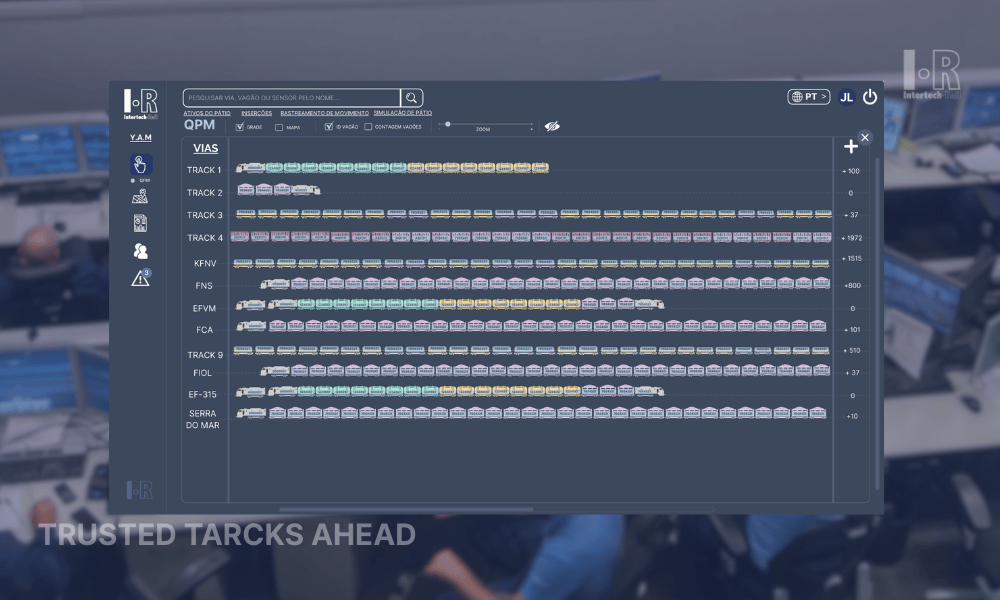

Where Railway Relays Are Used

These relay types play crucial roles in multiple railway infrastructure components, including:

- Signaling Systems – Provide clear, accurate signal indications to train operators.

- Track Circuits – Detect train presence and control track occupancy logic.

- Level Crossings – Trigger gates and alerts for both vehicle and pedestrian safety.

- Switch Operations – Control the precise movement and alignment of

railroad switches.

- Interlocking Systems – Ensure safe train movements through

coordinated switch and signal control.

Standards and Interoperability

All Intertech Rail relays are built to meet or exceed international standards such as AREMA, guaranteeing high performance and easy integration into modern railway switch mechanisms and control architectures. This ensures long-term reliability in both North American and global rail environments.