Digital Twin Technology in Railways: Virtual Modeling and Real-Time Simulation for Enhanced Operations

Understanding Digital Twin Technology in Railways

When you spend enough time around trains, you realize how many things happen at once. Wheels are heating up, switches are clicking, cables are humming, and it’s in constant motion. Now imagine seeing all that activity on the ground and on a screen, mirrored in real time. That’s the idea behind the digital twin.

Digital twins represent the cutting edge of railway digitalization. They turn the network into something visible, measurable, and, more importantly, predictable. A bridge between the rails you can touch and the invisible world of data that keeps everything running.

It’s not science fiction anymore. Railways worldwide already use digital twins to test, plan, and even rehearse what’s about to happen before it does.

How the Concept Works

The easiest way to picture it? Think of a “living copy.” The digital twin is a virtual railway version that reacts whenever the real one does. A vibration in a rail, a signal delay, or even a drop in temperature, the model changes instantly to match.

It starts with

data. Thousands of sensors send readings every second: position, voltage, axle load, temperature. The system turns that data into a simulation that behaves like the real thing.

Virtual replicas enable predictive maintenance and operational optimization. Operators can test different situations, storms, traffic jams, and mechanical stress, without putting a single train at risk. They can see where the system bends before it breaks.

That’s where the magic lies: in foresight, not reaction.

A Twin for Every Purpose

There isn’t just one kind of digital twin. The scope depends on what problem needs solving.

- Asset-level twins watch individual components like motors or sensors.

- System-level twins mirror the behavior of a full line or yard.

- Operational twins combine data from across the network into one dynamic model.

Together, they give engineers a way to look at the railway as a living organism instead of a collection of machines.

What It Changes for Operators

Every railway manager wants fewer surprises. Delays cost money, and unplanned maintenance breaks trust. With a twin, teams can see problems forming early. A slight increase in motor temperature might trigger an alert. A pattern in vibration data could hint at misalignment.

Instead of reacting, the system helps them plan. Maintenance windows get shorter, schedules more stable, and safety margins wider. It’s a subtle change that feels huge in daily operations. Predictive maintenance turns from buzzword to routine practice.

Beyond Maintenance

Once railways start using twins for maintenance, they quickly find other uses. Need to test a new timetable? Run it inside the model first. Wondering if a new section of the line will overload existing infrastructure? Simulate it.

Training also benefits. Operators can walk through emergencies in a safe, repeatable way. No passengers, no pressure, just practice.

This feedback cycle, observe, model, test, adjust, keeps networks learning and improving.

The Next Step

Technology never stops moving, but one rule still holds: better data means better decisions. As AI and connectivity grow stronger, the digital twin is no longer just a computer model; it’s becoming a real-time partnership between people and the systems they operate.

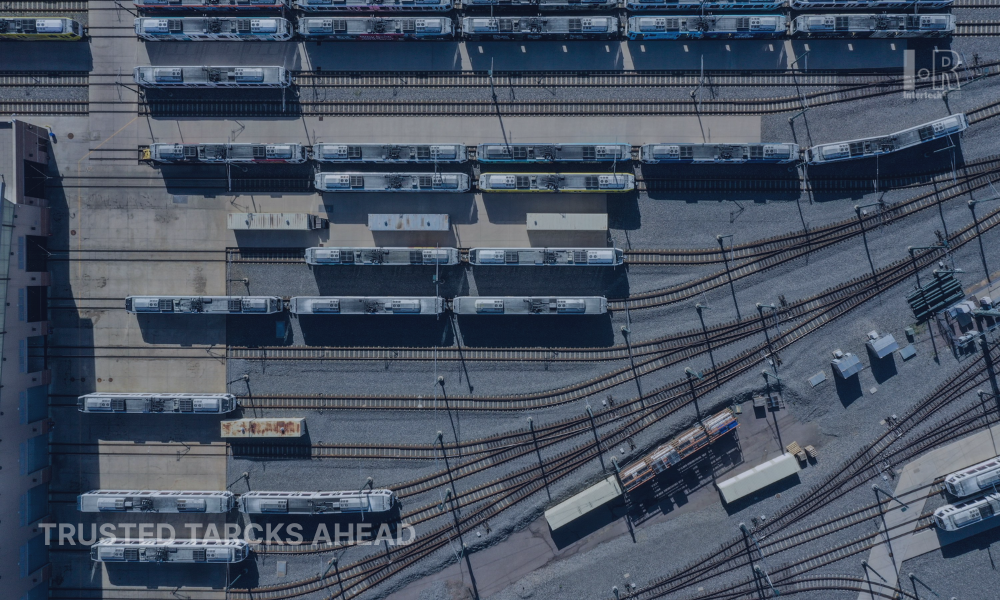

You can already see that in

Intertech Rail’s Yard Management System. It ties together data from AEI readers,

wheel sensors, and field devices, creating a live view of what’s happening in the yard, which train is moving, which switch just changed, and what equipment needs attention. It’s more than a dashboard; it’s the digital reflection of daily operations.

That’s what makes it part of the digital twin story. The system links physical movement to digital awareness, turning field data into something useful and immediate. It shows how Intertech Rail builds the foundation these technologies rely on, the solid layer of hardware intelligence that keeps virtual models honest.

The company doesn’t build digital twins itself, but it gives them life. Because a twin is only as good as the data that feeds it, and in railways,

trustworthy data is what keeps everything on track.

In the end,

the future of railways will belong to those who can turn real-world complexity into digital clarity, because better data doesn’t just improve operations, it redefines how railways think.

Image Sources: © Shutterstock/ AnyLogic