Asset Management and Lifecycle Planning: Maximizing the Value of Fail-Safe Relay Investments

Applying lifecycle thinking to optimize signaling performance, cost, and risk.

Applying lifecycle thinking to optimize signaling performance, cost, and risk

In railway signaling, assets rarely stop working overnight. They usually continue operating while becoming harder to support, more expensive to maintain, or less aligned with how the network actually runs. This is where lifecycle decisions start to outweigh technical specifications.

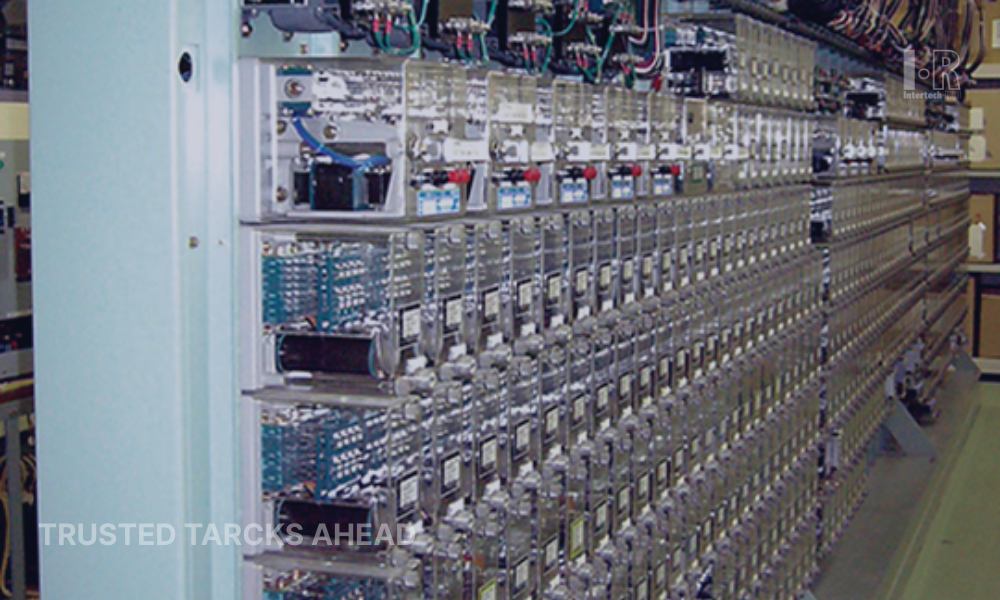

Fail-safe relays are a good example. They often remain in service for many years. Their value is shaped less by initial performance and more by how consistently they are managed over time. In this sense, asset management and lifecycle planning have a direct impact on operational stability and long-term costs.

A Strategic Approach to Railway Asset Management

Applying ISO 55000 principles to signaling assets

ISO 55000 treats assets as tools to achieve organizational objectives. For signaling systems, this means managing relays as part of a portfolio, not as isolated components. This approach helps avoid short-term decisions that later increase risk or cost.

Aligning asset decisions with organizational objectives

Signaling assets influence availability, safety performance, and budget predictability. Decisions driven only by purchase price often shift problems into maintenance and renewal phases. Lifecycle-based planning ensures that technical choices align with operational priorities.

Signaling systems as long-term critical assets

Relay-based signaling is designed for long service life. That longevity is useful, but it requires structure.

Balancing performance, reliability, and cost.

Higher reliability usually reduces disruption. Lower upfront cost often increases intervention frequency later.

Effective railway asset management weighs these effects across the full asset lifespan.

Lifecycle Management of Fail-Safe Relays

From procurement to end-of-life planning

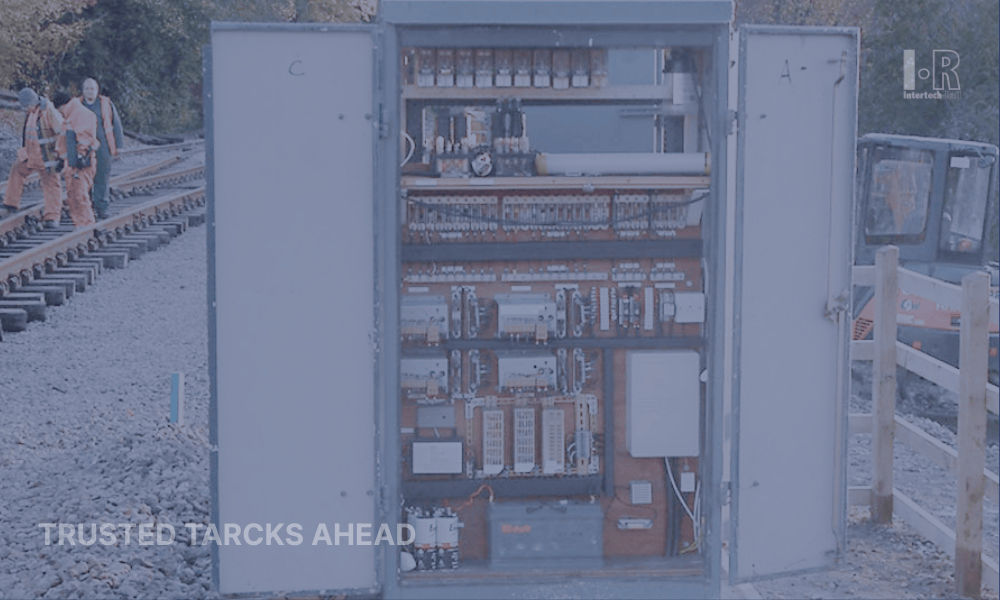

Lifecycle thinking starts at specification. Choices made early affect maintainability, spares availability, and compatibility.

End-of-life planning is part of the same process. Knowing renewal paths reduces pressure when support becomes limited.

Specification, spares management, and renewal strategies

Standard relay types, defined spares strategies, and clear renewal plans reduce dependency on emergency sourcing. These practices form the core of signaling lifecycle management.

Condition monitoring and maintenance planning

Fail-safe relays are often treated as static assets, but their condition changes gradually.

Using performance data to inform maintenance decisions

Basic performance data and operational feedback help identify trends early. This supports targeted maintenance while preserving safety margins.

Managing Obsolescence and Modernization

Proactive obsolescence risk management

Obsolescence develops quietly. Suppliers change, standards evolve, and expertise becomes scarce.

Early identification allows mitigation to be planned without operational disruption, consistent with ISO 55000 railways practices.

Phased modernization without compromising safety

Modernization does not require full replacement. New technologies can be introduced gradually while fail-safe relays continue enforcing core safety functions.

This approach reduces transition risk and maintains operational continuity.

In signaling asset management, value is preserved through deliberate lifecycle choices rather than reactive intervention. Fail-safe relay investments perform best when supported by structured planning, informed maintenance, and early obsolescence awareness, connecting engineering discipline with long-term operational and financial objectives.