Using Wheel Sensor for Train Positioning System

Wheels are a fundamental component of the railway system, enabling the movement of trains with efficiency and precision. Over the years, the development of wheel sensors has played a crucial role in enhancing railway safety, maintenance, and overall performance. These sensors have evolved significantly from simple mechanical devices to advanced electronic systems, revolutionizing the way rail operators monitor and manage their fleets.

The Evolution of Wheel Sensors: Advancing Railway Safety and Performance

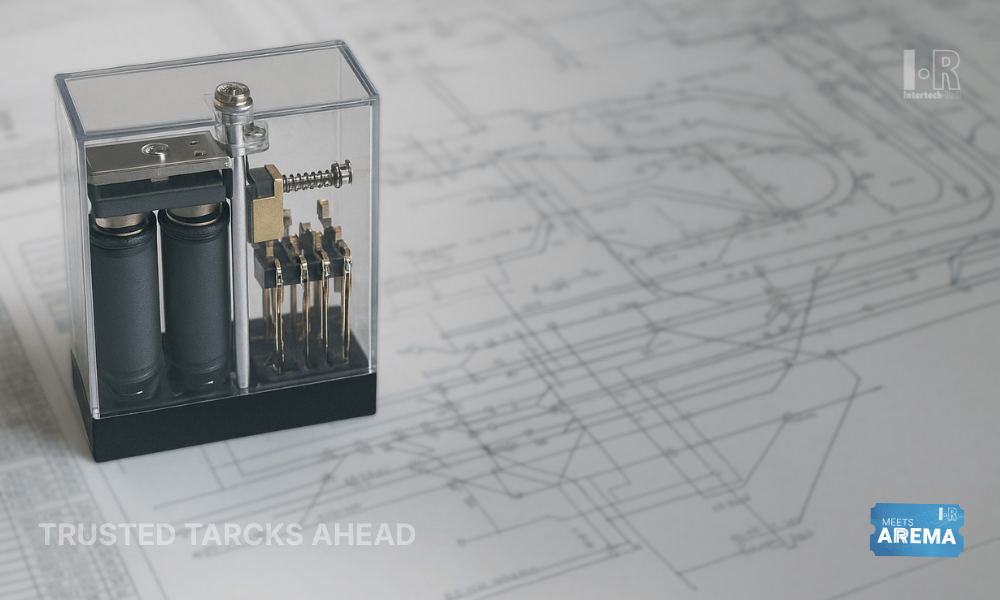

Early wheel sensors were primarily mechanical devices that relied on physical contact with the train wheels to detect rotations. They often featured mechanical switches or levers that would activate upon contact. While effective to some extent, these sensors had limitations. They were prone to wear and tear, required regular maintenance, and were not always accurate in providing real-time data.

With advancements in technology, electronic wheel sensors emerged as a superior alternative. The introduction of magnetic and inductive sensors revolutionized the field, offering greater precision and reliability. Magnetic wheel sensors, for example, used magnets and reed switches to detect the magnetic field generated by the train wheel. This technology eliminated the need for physical contact, reducing wear and maintenance requirements.

As digital electronics and microprocessors became more powerful and cost-effective, the evolution of wheel sensors accelerated further. Advanced electronic wheel sensors began incorporating sophisticated algorithms and communication capabilities. These sensors could provide real-time data on wheel rotations, speed, and even wheel faults such as flat spots or irregularities.

Advantages of Wheel Sensor-based Train Positioning

Accuracy and Reliability

Wheel sensors offer a high level of accuracy in determining the train's position and speed. By directly monitoring the wheels' rotation and movement, they provide real-time data, enabling precise positioning information. Unlike other systems that rely on external beacons or satellite signals, wheel sensors are immune to external interference, ensuring reliable performance even in challenging environments.

Cost-Effectiveness

Implementing wheel sensor-based positioning systems is often more cost-effective compared to alternative technologies such as GPS or trackside beacons. Wheel sensors are self-contained devices that require minimal infrastructure and maintenance, making them an attractive choice for railway operators aiming to enhance their positioning capabilities without significant investment.

Redundancy and Reducing Dependencies

Wheel sensors offer an additional layer of redundancy to existing train positioning systems. By combining data from wheel sensors with other technologies like GPS, the overall reliability of the system can be increased. Additionally, wheel sensor-based positioning systems reduce dependencies on external signals, making them suitable for underground or remote areas where signal availability may be limited.

Enhanced Safety Features

Accurate train positioning is vital for ensuring safety, particularly in scenarios such as switch point detection, collision avoidance, and maintaining safe braking distances. Wheel sensor-based positioning provides real-time information, enabling proactive safety measures to be implemented promptly.

Maintenance and Performance Monitoring

Wheel sensors can also serve as valuable tools for monitoring train performance and maintenance needs. By analyzing the data collected from the sensors, operators can gain insights into wheel wear, axle loads, and abnormal behaviors, allowing for proactive maintenance planning and reducing the risk of unexpected failures.

Challenges and Considerations

While wheel sensor-based train positioning systems offer numerous benefits, there are some challenges and considerations to be aware of:

Wheel Slip and Slide

Adverse weather conditions or poor track conditions may cause wheel slip or slide, potentially affecting the accuracy of wheel sensor measurements. Implementing sophisticated algorithms and data fusion techniques can help mitigate these issues and improve positioning accuracy.

Compatibility and Standardization

Interoperability between different train models and manufacturers can be a challenge. Standardizing wheel sensor systems and communication protocols can facilitate seamless integration across the rail network.

Data Integration

Integrating wheel sensor data with existing train control and management systems requires careful planning to ensure compatibility and effective utilization of the collected information.