Evolution of Switch Machines in Rail Industry

The rail industry has undergone significant changes over the past century, and one of the most important developments has been the evolution of switch machines. Switch machines, also known as turnout machines or point machines, are devices used to operate the points or switches on a railway track. The machines are used to ensure that trains can switch tracks safely and efficiently, and they have played a vital role in the development of modern rail transport.

In the early days of the

rail industry, switch machines were manually operated by railway employees. This required physical strength and coordination to operate, and was often a time-consuming and laborious process. However, as the rail industry grew and became more complex, engineers began to look for ways to automate the process.

The Evolution of Switch Machines in the Rail Industry

The first

automated switch machines were introduced in the early 20th century. These early machines were powered by electricity or compressed air, and were typically operated by a lever or pushbutton. They were more efficient than their manual counterparts, but still required a significant amount of maintenance and upkeep.

In the 1930s, the first remote control switch machines were introduced. These machines allowed railway employees to operate switches from a distance, reducing the need for physical labor and improving safety. Remote control switch machines were particularly useful in yards and other locations where multiple tracks intersected.

In the 1950s, the first computerized switch machines were introduced. These machines used electronic sensors and controllers to operate switches, and could be programmed to respond to specific conditions or events. Computerized switch machines were particularly useful in busy rail yards and junctions, where they could help to ensure that trains were routed safely and efficiently.

Since the 1950s, switch machines have continued to evolve and improve. Today, many switch machines are fully automated, and can be programmed to respond to specific conditions or events automatically. They are also much more reliable and require less maintenance than earlier machines, thanks to advances in materials, electronics, and other technologies.

Advancements and Applications of Switch Machines in Modern Rail Transport

The

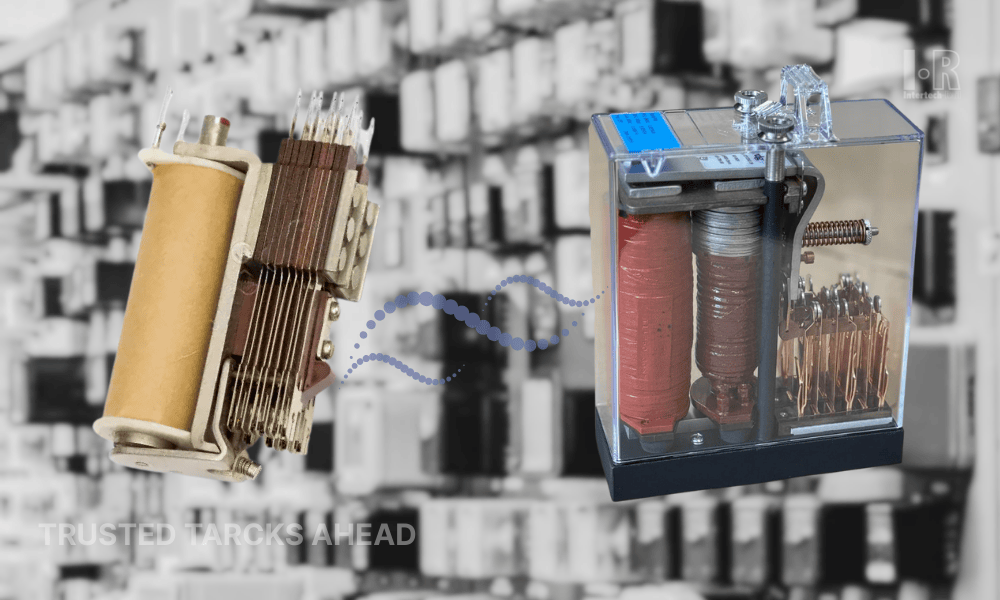

M-23 switch machine was a popular model of switch machine that was introduced in the mid-20th century. It was manufactured by the General Railway Signal Company. INTERTECH RAIL introduce the

IRM-23 Mainline as “pin-to-pin” compatible switch machine that is renewing the old M-23 installed park.

The IRM-23 switch machine was a motor-driven machine that used a worm gear to operate the switch points. It was designed to be rugged and reliable, and could be used in a wide range of applications, from small yards to busy mainline junctions. The machine was also known for its simplicity and ease of maintenance, which made it a popular choice among railway operators.

One of the key advantages of the IRM-23 switch machine was its ability to operate in harsh environments. The machine was designed to withstand extreme temperatures, moisture, and other environmental conditions, making it well-suited for use in areas with harsh weather or heavy industrial activity.